With the evolution of technology, we have been introduced to new machines, tools, and methods to work on wood. From hand saws to CNC machines, we have come a long way in improving speed, accuracy, ease of use, automation, and other considerable factors.

CNC machines are modern machines that automate the whole process of processing wood and other materials, making it easier and faster than ever before. These are the first choice of wood craftsmen, DIY enthusiasts, businesses, and professionals.

In this article, we will explore what wood CNC machines are, different types of wood CNC machines, benefits, popular projects, and everything else you need to know. We will help you in selecting the right CNC machine for your woodworking projects.

In This Article

- What is a Wood CNC Machine? How Does It Work?

- What Are the Benefits of Using CNC Machines for Woodworking?

- What are the Types of Wood CNC Machines?

- How to Choose the Best Wood CNC Machine for Your Woodworking Projects?

- Best CNC Woodworking Machine for Hobbyists

- Best CNC Woodworking Machine for Small Businesses

What is a Wood CNC Machine? How Does It Work?

Before we dive into the details of wood CNC machines, it is a must to understand what CNC is, why they are called CNC machines, and what kinds of machines people consider to be CNC.

CNC stands for Computerized Numerical Control. It is a kind of control established with the help of preprogrammed codes and software to control the machine. It is a numerical control, so it controls every part of the machine and its movement similar to our brain, which controls the organs and body parts.

CNC is an advanced control that is done through G-code, which is a special programming language. It makes the machine automated and processes the object according to the given instructions. In the past few decades, CNC has gone through significant evolution and improvement. Now, it is quite precise and accurate.

Many industries rely on CNC because it offers them the results needed in the shortest time possible and with minimal human involvement. It is quite efficient and productive for medium to high-volume production. It also reduces the labor requirement, so overall, the cost of production is reduced.

The machines that are controlled by CNC are known as CNC machines. It could be anything, such as CNC lasers, CNC grinders, CNC lathes, CNC routers, and CNC milling machines. These machines have a dedicated control that improves speed, accuracy, automation, and various other factors.

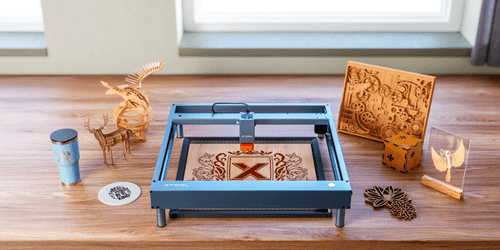

Wood projects made by CNC laser machines

You might have seen old-schooled lathes, routers, grinders, and other machines. They need an operator that constantly operates the machines and controls the movements of the parts. CNC machines have completely changed the usage of these machines. Through a control unit, preprogrammed code, software, and other requirements, the machine is controlled.

Wood CNC machines are used for subtractive manufacturing because all these machines remove the material from the surface. Whether it is a laser machine, lathe, or router, all these remove the material from the object. The user provides a design, CAD file, or any other compatible version through the software. Then, the machine follows the instructions and turns the wood into the desired shape, size, or cut.

What Are the Benefits of Using CNC Machines for Woodworking?

Automation

The first benefit of using CNC machines for woodworking is automation. The machinists have to provide the design through the software and fill in all the required settings and details. Once the machine is started, everything is done automatically. There is no need to operate the machine or do anything. The machine follows whatever instructions are provided, and it stops after completing the job.

Time-saving

Woood CNC machines are quite fast because of automation and minimal human involvement. The machines work at an incredible pace and do the job in no time. With that being said, these can increase productivity, and you can process high volumes. This is the reason industries and large-scale businesses prefer CNC machines. These save time and improve efficiency.

High Accuracy

If there is any human involvement in creating a product, there are chances of errors. You cannot even make identical products every time. But CNC and other automated machines offer high accuracy. You won’t see an error of a fraction of a millimeter. If you make several pieces using the machine, all will be identical. Thus, if accuracy is the main concern, there is nothing better than automated CNC machines.

Safety

CNC machines are much safer than traditional machines. The reason behind it is automation. The operator only has to provide the instructions through the software, and the machine does the job. So, the operator is safer. In contrast, a traditional lathe operator is exposed to various hazards. He can even cut his fingers and injure himself.

Reduced Cost

CNC reduces the overall production cost. First of all, it reduces the number of persons required to operate the machine, which means less manpower is needed. Secondly, it works at a fast pace and increases productivity, which ultimately reduces the price of production. It can also help in scaling the business.

What are the Types of Wood CNC Machines?

CNC Wood Router

A CNC wood router contains a sharp rotating blade that cuts and engraves wood and other materials. It removes the wood from the surface and gives it the desired shape and engraved texture.

The part of the machine that holds the rotating blade is called Spindle. It rotates the blade at different speeds according to the requirements. The material that needs to be processed is placed on the working bed, and then the machine is started.

The machine moves the spindle on X, Y, and Z axes to control the movement of the blade and turn the object into the desired product. This movement is done with the help of a drive system that contains several powerful motors. The spindle is moved precisely to ensure accuracy during the subtractive manufacturing process.

The whole machine is controlled by CNC. It requires a design for the task, so a CAD designer is needed. This design is communicated to the machine through the software. The software or preprogrammed code reads the design or the CAD file, and then it provides the G-code to the CNC. Finally, CNC commands the drive system to move the spindle in the desired direction. It controls every part of the machine as needed to achieve the results.

People often get confused between a CNC router and a CNC laser. They often think that both can do engraving and cutting, so they are the same. However, there is a massive difference between these two CNC machines.

A CNC router creates physical contact with the object and removes the material from the surface by using a sharp blade. But a laser machine does not make physical contact. It burns wood and offers perfect cuts using a laser beam. The engraving gives an appealing contrast because of the burning.

CNC Wood Milling Machine

A CNC wood milling machine is also used for cutting and engraving materials. It can turn the material into the desired shape. It also contains a rotating end mill that cuts the materials similar to a drill bit but it works in all directions.

This machine also has a spindle that holds the end mill. The driver system moves the spindle in the required directions to get the desired results. The design is provided to the software through a CAD file, which is then translated into G-code.

A CNC milling seems to be similar to a CNC router, but there are some differences. A milling machine is specifically designed for harder materials, such as metals; however, it can also work on wood and acrylic. In contrast, a router is only suitable for soft materials, such as wood. The compatibility with materials is a major difference between these machines. Secondly, the speed of the end mill in milling machines is slower, but the torque is quite high. This is the reason it can cut hard materials easily. Thus, the whole process takes more time. The working area or bed of routers is larger than CNC milling machines, but their Z-axis is quite limited. Therefore, they can handle large objects. But CNC mills have a smaller area for the objects and deep Z-axis.

CNC Wood Lathe

A CNC wood lathe is used for shaping or carving objects. It can be used for wood and various other materials. There is rotary on the machine that holds the objects in its jaws. It revolves around the spindle. The object revolves at a very high speed through a controlled motor. Then, the blade of the lathe is moved toward the object. It removes the material from the surface and creates the desired shape. Similar to other CNC machines, it also requires the CAD file to provide the instructions. Once it has the design, it turns wood on its own.

Laser CNC Machine for Wood

Laser CNC machines are ideal for cutting and engraving wood, acrylic, leather, cardboard, rubber, and various other materials. These machines use powerful laser beams produced by a laser source. The source of the laser can be a CO2 laser tube, diode, or any other technology, depending on the type of laser machine. The laser beams come out of the laser source and are reflected through mirrors in the desired direction. Finally, all laser beams are confined at a small spot through a convex lens. These beams increase the temperature of the object they touch within a fraction of a second.

The temperature is increased abruptly, which causes the change of solid into gas. This direct change of the states without going through the intermediate stage is called sublimation. Thus, the material is vaporized and removed from the surface of the object in a matter of seconds. Finally, you have a cavity that serves as engraving. If the power of the laser is high, then it cuts the material into pieces.

In the case of wood, the material burns due to the high temperature. The heat from laser beams burns material from the surface and turns it into smoke and ashes. It offers an incredible contrast, which looks appealing.

Laser cutting and laser engraving is an advanced technology that has made cutting materials like wood, acrylic, metals, and other materials easier than ever before. It is a safer, quicker, and perfect option. The most important thing about laser processing is the finishing you get at the end. The final products have an impeccable and eye-catching finish.

Suitable CNC Laser Machine for Wood

Laser machines can process a wide range of materials, but it actually depends on the type of laser technology it is using. Each laser machine offers a certain wavelength of laser beams, and materials absorb specific wavelengths only. If the material can absorb the wavelength, it can be cut or engraved without any hassle.

For processing wood, the ideal CNC laser machines are CO2 and diode lasers. CO2 lasers are quite powerful, and they are available in various sizes from desktop machines to industrial machines. These are more expensive due to the laser technology and other features in the machine. A desktop CO2 laser will cost over $3,000, but the commercial ones are over $10,000.

On the other hand, diode lasers are quite affordable. These can process wood, plywood, and engineered wood with utmost perfection. They are less powerful than CO2 lasers but can still do the job well at an incredible speed. They are suitable for DIY, hobbyists, and professionals. A desktop laser machine will cost you around $700 to $1,500.

You can choose a CO2 or diode laser, depending on the budget and usage. Both can cut and engrave wood. If you have a good budget and want to run a small business, select a CO2 laser machine. For DIY and similar tasks, you can go with a diode laser machine.

What You Can Do Using a CNC Laser Machine

The laser has a fine spot that considers tiny details and cuts even small pieces with perfection. You can cut intricate patterns and almost any kind of design using a laser machine. These are quite precise, and you won’t get better results with other types of CNC machines.

With laser cutting, you can make products from scratch. For instance, you can make wall art pieces, wall clocks, wooden boxes, jewelry organizers, puzzles, toys, keychains, and tons of other things. It allows you to cut wood in any shape you like and turn your imagination into reality.

On the other hand, laser engraving is basically used for personalizing objects. You can make logos, write names, engrave photos, or do whatever you like. Nowadays, personalized objects are quite trending. Using a laser machine, you can personalize keychains, wooden cutlery, wall hangings, signs, plaques, and tons of other things. The laser engraves whatever you want, and the best part is that it offers an appealing contrast due to the burning of wood. The result of laser engraving is better than other engraving techniques.

Thus, there are uncountable woodworking projects you can do using a CNC laser machine. This machine can be a game-changer. You can turn your imagination into reality and sell your products online through social media and online marketplaces. It is one of the trending and profitable businesses and side hustles these days.

Most importantly, if you have a CNC laser machine, you can process a wide range of materials other than wood. It is a versatile machine that can take your creativity to the next level. You will have a massive range of products in your inventory.

How to Choose the Best Wood CNC Machine for Your Woodworking Projects

CNC machines are quite expensive, which is why you have to consider every detail and factor to save time and money. Here are some of the important factors you need to consider to get the right CNC machine for your projects.

Type of the Woodworking Projects

The first thing that you need to look at is the type of woodworking projects you want to work on. It can be furniture making, doors, laser marking/engraving, etc. You have to consider the projects you want to cover, and then it will be easier for you to pick the right machine for your needs.

The machines we have discussed serve different purposes. So, you need to understand what each machine does to decide which one is suitable for your tasks.

Material the Machine can Process

You will be processing wood, so the CNC machine should be able to process it. But it is not enough. Sometimes, you need to process other materials as well to add more beauty to the products and make them versatile.

Check what materials can be processed in the machine. For instance, a CO2 laser can process wood, acrylic, leather, rubber, etc. A milling machine is ideal for working on hard materials, such as metals. So, you need to know what materials the machine can process, and then it will be easier for you to choose the right wood CNC machine.

Maximum Volume Capacity

In CNC machines, it matters a lot. You are buying it for manufacturing in bulk. Each machine has a maximum capacity. You can check it to know what you can do with the machine, how many machines you need for your goal, and how you can scale in the future. Once you have a clear idea of the capacity, it will be easier for you to invest in the right direction.

Speed

CNC machines have a specific speed limit that gives you an idea of the number of items you can make and which machine is faster. People prefer these machines because of their speed and efficiency. They are meant to increase your overall productivity. Therefore, always compare the speed of the machines to get the best deal.

Spare Parts and Maintenance

CNC machines require maintenance. Before buying one, you should have an idea of the maintenance and how it can be done. Secondly, often there can be issues with the parts in the future, so the spare parts should be easily available. Otherwise, the machine will become a headache.

Budget

Last but not least is the budget. CNC machines are expensive, so you have to consider your budget and select the right option. There are different variants of machines due to distinct sizes, features, and other specifications, so the price differs.

If you want to engrave materials at a low cost, you can go with a small desktop laser machine. It will do the job without any massive investment, but it is ideal for DIY and small businesses only. Similarly, you can also go with desktop CNC routers and milling machines.

Best CNC Woodworking Machine for Hobbyists

xTool D1 Pro is an extremely powerful desktop laser machine for DIY enthusiasts and hobbyists. It is a diode laser machine that can cut hardwood, softwood, plywood, MDF, acrylic, rubber, leather, cardboard, etc. It can engrave the materials it can cut and some other materials, such as glass, ceramics, stone, and metals.

The machine has state-of-the-art diode laser technology. It is equipped with the world’s first 40W diode laser module. It can cut thick pieces of wood, such as 20mm pine wood, 18mm cherry wood, and 15mm black walnut, in only one pass. It makes cutting easier and faster and offers incredible results without any compromise on quality.

Wood projects made by xTool D1 Pro

You can use the 10W laser module for engraving wood, acrylic, and other materials. The module has a very fine laser spot measuring 0.08 x 0.06 mm, which covers the fine details. It can engrave at a magnificent speed of 400mm/s. Thus, it saves a lot of time and increases your productivity.

The machine is also compatible with the infrared laser module, which is ideal for acrylic and metal engraving. It is used for engraving jewelry items because it can engrave precious metals as well. Thus, xTool D1 Pro is a complete package for engraving and cutting a wide range of materials, especially wood.

By using the RA2 Pro rotary attachment, you can process 90% of the cylindrical and spherical objects. It is possible to engrave tumblers, rings, glasses, balls, Christmas baubles, pens, and a wide range of items.

The movement accuracy reaches up to 0.0004 inches and the repositioning accuracy is up to 0.0007 inches. It takes care of the fine details, and you won’t see errors and issues in the final products. You can process multiple objects at the same time and get identical results.

It is possible to upgrade the machine because it can go with new laser modules. You can attach the extension kit to increase the working area of the machine. Normally, you can process materials measuring 430 x 348 mm, but this area is doubled after installing the extension. You can use air assist, rotary attachment, enclosure, and various other accessories.

xTool D1 Pro is a beginner-friendly machine and anyone can use it without any prior experience. It is safe for home, garage, and small office use. It has flame detection and tip-over safety to prevent accidents and misuse of the machine. If you want to take your creativity to the next level, it is an excellent laser engraving and cutting machine.

Best CNC Woodworking Machine for Small Businesses

xTool P2 is a versatile, smart, and powerful CO2 laser machine that is equipped with incredible features. It is an excellent option for starting a small business from home, garage, or small shop.

The machine has an incredible optical power of 55W, which can cut wood and other materials without any hassle. It is possible to cut 20mm acrylic and 18mm black walnut wood in only one pass. The cutting speed of the machine reaches up to 250mm/s and the engraving speed can reach up to 600mm/s. It saves you a lot of time and improves your productivity.

The automatic passthrough of the machine allows you to work on large objects up to 118 inches. You can install the automatic feeder, which works like a conveyor belt. This is a commendable feature, and you will find it in high-end and expensive machines only.

Secondly, the machine can engrave any irregular object. It creates a 3D model of the object and engraves curved surfaces with perfection. The focus is adjusted automatically according to the shape of the object.

The machine can process multiple objects at the same time. The 16MP cameras give a complete view of the working area. You can have the panoramic view as well as the close-range view. It is also compatible with the rotary RA2 Pro. Thus, you can engrave cylindrical and spherical objects in the machine. All these features make the machine versatile, and you can have a wide range of products in the inventory.

You can use the machine in a closed space without any hassle. It is an enclosed machine, and there is a built-in air assist and exhaust system. The smoke and smell are expelled out of the machine through the pipe. You can also attach an air purifier to the machine and clean the exhaust air to keep the environment safe and healthy.

There are tons of safety features in the machine. There is a warning system. You can also connect the fire safety kit to extinguish the fire automatically to prevent accidents. Overall, the machine is incredible, and it is almost impossible to get such features at this price range. It is worth every penny, and your investment can be easily recovered through the business.

Related Articles

Best Laser Engraver for Metals in 2024

Metal Engraving Tools: How to Choose Your Right One