Nowadays, we have tons of metal objects that require metal engraving. For instance, some jewelry enthusiasts like to get their jewelry engraved and customized with names, dates, or anything they like. Similarly, trophies, medals, plaques, and various other items are engraved to make the metal piece more appealing. Companies also prefer the company name, logo, QR code, and other details on their metal products, and this is only possible through metal engraving.

Metal engraving is not as easy as engraving a piece of wood because of its hardness and high boiling & melting temperatures. Therefore, special and advanced tools are needed to get optimal results.

In this article, we are going to explore how metal engraving is done, what tools are suitable for the required job, and how to choose the right machine. We will try to explain every aspect in simple words with complete details so that you can understand metal engraving easily even if you are a beginner.

In This Article

- Types of Metal Engraving Tools

- How to Choose a Metal Engraving Tool?

- Best Metal Engraving Tools for Beginners

- FAQs of Metal Engraving Tools

Types of Metal Engraving Tools

Metal engraving is done by using various tools, and all of them have their distinct features, pros & cons, budget, and other specifications. Let’s understand these tools to know what you exactly need for your projects.

1. Metal Laser Engraving Machines

Laser engraving is an advanced method of engraving metals and other materials with powerful and automated machines. It has made engraving of materials faster and easier than ever before. The quality of the engraving is exceptional due to its high accuracy and fine details. It is difficult to achieve such commendable results through any other method of engraving.

In laser engraving of metals, the laser engraver produces powerful laser beams that are focused at a tiny spot. When these beams fall on any compatible material or object, the temperature of the material starts to increase abruptly. Within a small fraction of seconds, the temperature of the material reaches the boiling point, which turns the material into vapors. Thus, the material changes its state from solid to gas without going through the liquid phase, this process is also known as sublimation.

When a metal is engraved using a laser, the material from the surface is removed. Therefore, a cavity is created, which gives a 3D appearance. Laser engraving of metals is not easy because a powerful laser is required that can increase the temperature of the material to melting or boiling point.

In the case of metals, there are different reactions of laser beams. There are various types of laser marking that are used on metals. Some of the commonly used methods for marking metals are laser engraving, laser annealing, laser foaming, laser carbonizing, laser coloration, etc.

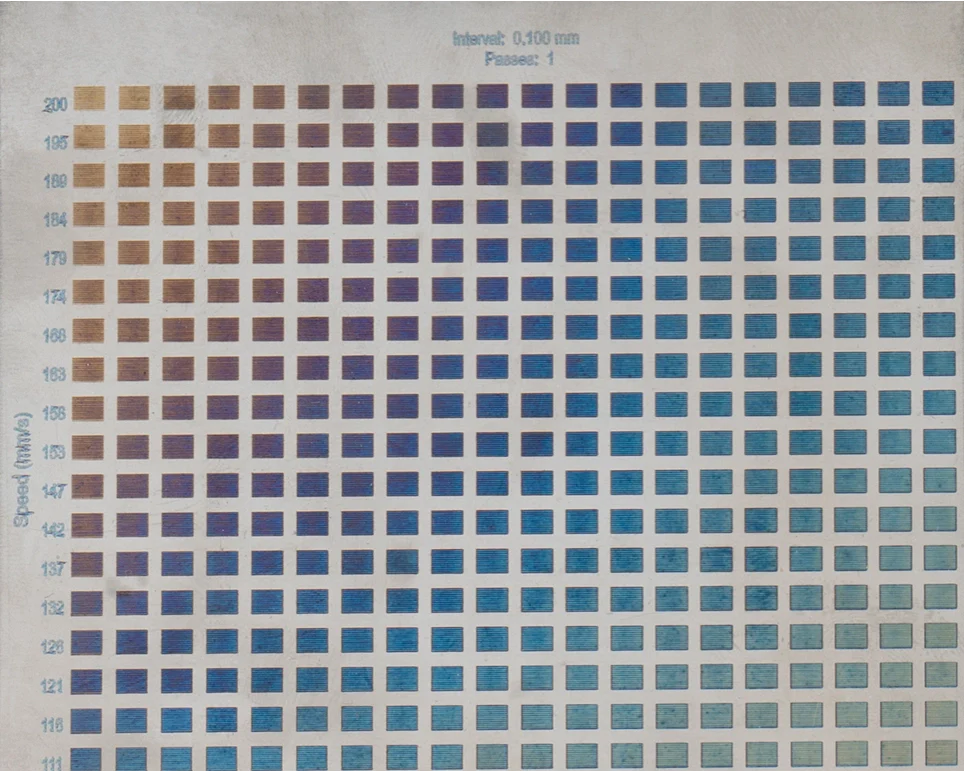

Desktop laser machines usually do laser annealing and laser coloration. In both methods, the metal is marked at lower power, and there is no cavity created. It only affects the surface level, and the color of the metal changes according to the power, speed, and other settings. With the change of laser settings, the results of the laser marking or engraving can be changed.

Usually, small businesses, DIY enthusiasts, and professionals prefer desktop laser machines due to their minimal cost. Different types of metals, such as stainless steel, titanium, steel, iron, and various other metals are processed, including precious metals. However, it all depends on the laser technology.

Benefits of Using Laser Machines for Metal Engraving

No Physical Contact Process: The primary benefit of a laser engraving machine is that it is a non-contact engraving process. The laser machine does not touch the material due to the laser beams. Therefore, there is no chance of wear and tear on the object. The leftover material can also be used again.

High Accuracy and Precision: Laser machines offer incredible accuracy and precision. The machine can reach an accuracy of up to 0.0004 inches or more. Even if you do intricate engraving, you won’t find any errors in the results. The motors of the machine are extremely precise and accurate, and you can make dozens of items, and all will be identical.

The laser spot of a laser machine has minimal dimensions. It is quite small that the Kerf width of cutting is negligible in most cases. The small spot can consider the fine and tiny details for graphics and makes engraving more beautiful.

Commendable Speed: The speed of laser machines is commendable. They can engrave at a speed of 400mm/s or even more, depending on the power and other specifications of the machine. It can engrave faster than other engraving methods and machines.

Automated Process: Laser engraving is an automated process. Once the design is uploaded, the machine does everything on its own. Therefore, it is a fast and efficient method for engraving. You can process multiple objects at the same time, which is ideal for businesses. It increases overall productivity.

Types of Laser Machines

Laser machines are available in various technologies. Each technology has compatibility with certain materials, upfront costs, and other benefits and limitations. You have to choose the right laser machine for your metal engraving for optimal results.

Infrared Laser: Infrared laser machines can process a wide range of metals, including stainless steel, iron, titanium, aluminum, copper, gold, silver, platinum, and various other metals. The wavelength of these laser machines is around 1064nm, which is quite favorable for metal engraving and marking. The metals can easily absorb such laser beams and offer incredible results.

For jewelry engraving, infrared lasers are ideal. These are also good for laser engraving acrylic and other types of plastic. There are handheld infrared laser machines as well as desktop infrared laser machines. These are the most affordable lasers for metal engraving. They contain diodes that emit laser infrared laser beams. The technology of the laser machine is quite simple, and there is no optical fiber used, which is why these machines have a low cost. You can use them for DIY, small jewelry engraving business, remote jobs, or any other purpose.

Diode Laser: Diode laser machines also contain diodes that emit laser beams, but these lasers produce beams that have a wavelength of around 450nm. Ideally, these machines are suitable for wood, plywood, MDF, acrylic, stone, ceramics, leather, and similar materials. But if the optical power of the laser machine is high, around 20-40W, then these machines can also engrave metals. Diode laser machines oxidize metals and offer various colors on different types of metals. These colors depend on the power and speed settings. But keep in mind that not all diode laser machines can do metal engraving. If you want to buy any specific diode laser machine, make sure the manufacturer recommends it for metal engraving and its power is high.

Fiber Laser: Fiber lasers are specifically used for processing metal. These are quite powerful, and they can engrave, weld, clean, and cut metal materials. The reason behind this is the fiber optics used inside these laser machines. The fiber optics cable is doped according to the requirement, such as engraving, cutting, cleaning, etc. The final wavelength of these machines can vary from 780 nm to 2200 nm, and the desired wavelength is achieved through doping.

These laser machines are the first choice for metal engraving. They can remove metal from the surface and create a cavity. The wavelength can easily be absorbed by a wide range of metals, including precious ones.But these machines are quite expensive. If you want to engrave metals on a large scale for a business or any other purpose, you should go with it. They are the best of all laser machines when it comes to metal engraving.

CO2 Laser: CO2 lasers are used for engraving and cutting non-metals. These laser machines produce laser beams with a wavelength of around 10,600nm, which is suitable for most non-metals and a few metals. However, they can also mark some metals by changing their color. It is the least preferred option for metal engraving, but if you already have one, you can give it a try.

2. CNC Metal Engraving Machines (CNC Milling Machines)

CNC milling machines are one of the preferred choices for engraving metals. These machines have a very sharp drill bit, which is called an end mill. They can easily engrave hard materials, such as metals. However, you can also use the machine on soft materials. The milling machine creates physical contact with the object and removes the material from the surface. It does not change the color of the object in any way because there is no heating or oxidation involved. The material is removed from the surface with perfection, and the depth can be controlled as required.

image credit: MYSWEETY

The end mill can easily engrave hard materials because of the high torque of the machine. It moves in every direction and turns the object into the desired shape. Thus, it is not only for engraving but also for carving.

The most important thing about these machines is their accuracy. These offer fine details and high-quality engraving results. Professionals prefer them for making parts of sensitive and high-end objects, such as satellites, military equipment, medical equipment, etc.

Milling machines can be simple desktop machines or high-end CNC machines. Desktop machines are inexpensive. On the other hand, CNC milling machines are only suitable for large-scale businesses, factories, and industries because of their high cost. However, these machines are automated and controlled through advanced pre-programmed code and software. They offer complete automation, optimal results, and high-speed processing. Due to complete automation, there is minimal human involvement. It is a safer option compared to traditional lathe and milling machines. These are undoubtedly quite expensive, but they are worth it.

3. Hand Metal Engraving Tools

Hand engraving tools include simple hand tools called gravers. These are similar to chisels, which are used for wood crafting, but they are specifically made for engraving metals. There are metal carving tools, special metal engraving chisels, engraving knives, etc. All these tools have a sharp blade and a wooden handle. A special type of hammer called a chasing hammer is used to strike the back of graver tools. It is a traditional method of engraving and shaping metals. If you want to do engraving with it, you need expertise, and it takes a lot of time to engrave a simple design on the object. Hand metal engraving tools are used for jewelry making, and even in this era, jewelers prefer using hand tools for shaping and engraving jewelry.

4. Electric Metal Engraving Tools

Electric metal engraving tools are actually mini tools like handheld devices. It is similar to a 3D or handheld drill. These are known by different names, such as rotary engravers, engraving pens, and handheld engraving tools.

Basically, these tools have a drill bit, which can be used for engraving metals. Due to tiny drill bits, it is possible to consider fine details during engraving, but it is a manual process. An expert is needed to use the tool and engrave the design on the metal. For small engraving tasks, these are excellent. For instance, if you want to engrave a name or number of a metal object, you can use them. But the quality of engraving depends on the operator. It requires exceptional skills and experience. There is a wide variety of these tools available. These are compact, portable, and cheap. Therefore, they are ideal for small tasks and DIY.

How to Choose a Metal Engraving Tool?

Before purchasing metal engraving tools, you need to consider a few factors. It will help you choose the right tool according to your needs.

The Usage of the Engraving Machine

If you want to choose the right tool for metal engraving, you need to decide the usage of the tool first.

For instance, if you want to engrave images, logos, intricate patterns, high-quality graphics, and similar things, the ideal option would be a laser engraving machine because it can do with utmost accuracy and precision. You will get phenomenal results that you can’t get from other tools. Secondly, a laser machine changes the color of the engraved area, so if you want colors, oxidation is only possible through a laser engraver.

If you want to engrave as well as shape a piece of metal, then CNC milling machines are the best. These can engrave the material to the required depth and shape it as you like. The sharp blade creates physical contact with the object and removes the material physically. But keep in mind it is suitable for large-scale businesses, high-end products, and intricate parts of machines and objects.

For simple engraving tasks, such as engraving names, dates, quotes, and numbers on various objects, you can go with an electric tool. It will help you do the job without investing a massive amount. However, it is only suitable for DIY.

For jewelry engraving and shaping, hand tools can be used. But the accuracy and precision depend on the user. Moreover, jewelry engraving can also be done through a laser engraving machine.

Expertise

Metal engraving tools require some expertise, experience, and knowledge. If you are a beginner who does not have the skills to use hand/electric tools, you need to go with a laser engraver or CNC milling machine. These are automated machines, and beginners can use them after reading some guides and watching tutorials. These machines only require the design, and the rest is done automatically. Hand engraving tools as well as electric engravers require skills and expertise. Not everyone can handle these machines. So, depending on your expertise, you can choose the right metal engraving tool.

Compatible Metals

There is a compatibility of metal engraving tools. For instance, some engraving tools are not suitable for precious metals. Check the compatible metals to know what you can do and what you cannot.

Speed

The speed of the metal engraving tools decides productivity. Laser machines are the fastest because they can engrave at an incredible speed. It does not matter how intricate the graphics or design is, these machines can do everything at an exceptional pace. CNC milling machines are also fast, and they can do intricate jobs quickly. But if you are using hand tools or electric tools, it will take more time to engrave the same design or graphics. For businesses, laser engraving machines and CNC milling machines are the most suitable ones.

Accuracy

In metal engraving, accuracy plays a very important role. The movement of motors, the control of the blade/laser, and fine details define the quality of the engraving. If accuracy is the main concern, you should go with a laser engraving machine or CNC milling machine. While using hand tools and electric tools, there is no guarantee of accuracy and precision because it depends on the user/operator.

Safety Features

Check the safety features of the machine, and whether they are safe for the users or not. If you are buying a laser machine, check its safety features. It should have a fire alarm, tip-over safety, and an emergency button. Similarly, CNC machines also have various safety features. You need to consider them before choosing a machine.

Budget

Budget is the most important factor when buying metal engraving tools. The cheapest metal engraving tools are hand tools. You can get a set of these tools for $10-$50. Next in the line are electric engraving tools. These cost around $10 to $100. Then, there are laser engraving and cutting machines. The diode and infrared lasers are the most affordable ones and then comes the CO2 laser. Fiber lasers are the most expensive lasers, but they are ideal for metal engraving. CNC milling machines are very expensive because of the CNC automation. These machines are advanced and suitable for large-scale businesses.

Best Metal Engraving Tools for Beginners

xTool D1 Pro is an incredible laser machine suitable for beginners, DIY enthusiasts, artists, and professionals. It will make laser engraving a lot easier, faster, and more accurate.

The best thing about the machine is that the user can change the laser module. It comes with a diode laser module. You can choose the world’s first 40W diode laser module and engrave metals with vibrant colors. The module is powerful enough to oxidize a wide range of materials and change the color of the surface instantly. It can bring 340+ vivid colors according to the material and the selected settings.

The ideal laser module for metal engraving is the infrared laser module. It is specifically made for engraving almost all metals, including stainless steel, copper, iron, aluminum, gold, silver, and platinum. It offers 1064 nm laser beams that are ideal for metal and plastic engraving. You will get perfect metal engraving results at an ultra-fast speed of up to 400mm/s.

The machine is compatible with rotary attachment RA2 Pro, which can process almost 90% of cylindrical and spherical objects. Engraving rings, bracelets, pendants, bangles, and other irregular items are quite easy with the rotary attachment.

Secondly, there is a large working area of about 430 x 390 mm, which is excellent for working on a wide range of objects. Moreover, this area can be doubled by installing the extension kit.

This is a versatile machine. You can use the 10W, 20W, 40W, and infrared laser modules whenever you want. Thus, you can engrave metals, wood, acrylic, leather, ceramics, stone, and a wide range of materials. Secondly, it can also cut various thick non-metals at an incredible speed.

The movement accuracy of the machines reaches up to 0.0004 inches, and the repositioning accuracy can be up to 0.0007 inches. Thus, you will get perfect results even if there are tiny details. Its stable design and powerful motors make it accurate and precise. You can engrave precious metal items without any worries.

The machine is perfect for beginners. It is affordable, easy to use, and upgradeable. Users can use its simple native software for the projects, which is available for free. It also offers fire detection, an emergency stop button, and tip-over safety to prevent accidents and ensure safe usage of the machine. It is a plug-and-play machine that makes metal engraving a lot easier and faster.

FAQs of Metal Engraving Tools

What is the best tool for engraving metal?

For metal engraving, laser machines are ideal because they offer high accuracy, incredible speed, and exceptional results. Even beginners can easily use a laser machine and engrave metal with utmost perfection. There is no need for expertise or any prior experience. It is simple, quick, and up to the mark.

The laser beams create the desired design without touching the object. The quality of the output is ensured, and there are minimal chances for errors. Thus, if you want to engrave metal with utmost accuracy and high-quality graphics, there is nothing better than a laser engraving machine.

How to do metal engraving?

If you are using a laser machine, you only need to upload the desired design to the software and adjust the settings. Then, place the material in the working area, and start the engraving process. The machine will do everything on its own. The laser beams will engrave or oxidize the metal and create permanent marks on the object. It will replicate the desired design on the metal with fine details and high-quality graphics.

Related Articles

Best Laser Engraver for Metals in 2024

Metal Engraving Tools: How to Choose Your Right One