Laser marking technology has revolutionized the process of marking materials, making it more efficient and precise than ever before. With cutting-edge innovations, these machines deliver outstanding results in a matter of moments, streamlining the marking process and significantly reducing time and effort.

As a new user entering the world of laser marking, selecting the appropriate machine can seem daunting due to the technical nature of the decision. With numerous laser marking machine types on the market, it is essential to have a thorough understanding of their intricacies in order to make an informed choice based on your specific needs.

In this guide, we will delve into the basics of laser marking, examining its various types and how they function. Additionally, we will outline crucial factors to consider when selecting the ideal machine, as well as the most suitable options for marking a diverse range of materials. Ultimately, our goal is to assist you in identifying the best laser marking machine for your needs in 2023.

In This Article

- What is Laser Marking and How Laser Marking Works?

- Types of Laser Marking

- Types of Laser Marking Machines

- Factors to Consider When Buying a Laser Marking Machine

- Best Laser Marking Machine

- Conclusion

What is Laser Marking and How Laser Marking Works?

In the past, marking materials required manual labor, utilizing chisels and hammers to emgrave logos, identification numbers, and other designs. Today, we have modern, efficient, and precise marking methods that eliminate the need for laborious work, such as laser marking. Laser marking involves using laser beams to create long-lasting, permanent marks on a wide variety of materials, such as wood, leather, metals, acrylic, and even diamonds. By selecting the appropriate laser machine for the specific material, high-quality marking can be achieved with ease.

Unlike traditional marking methods, such as CNC routing, drilling, and manual marking, which involve physical contact with the material's surface, laser marking is a non-contact process. This ensures pristine results without damaging or compromising the material's integrity.

Laser beams are generated from a laser source, such as a CO2 tube or a laser diode, and focused on a single point using a convex lens. The resulting spot is typically minuscule, allowing for detailed and precise marking on the material. As the highly concentrated beams make contact with the material's surface, marks are created on the material due to the high temperature of the focused beams. They alter its physical properties, causing a visible change in appearance due to the transfer of energy. These marks have a contrast, which is why they are visible and clear.

The advantages of laser marking are numerous, including ease of use, exceptional speed, and the ability to handle large volumes without hassle. Furthermore, the process only requires uploading the desired design or text to the laser engraver software, and the machine autonomously completes the marking. Laser machines boast incredible accuracy and precision, capturing even the smallest details for exceptional results. Moreover, since the process is contactless, it is safe for both the user and the material, preventing damage or injury.

Due to these benefits, laser marking is an ideal choice for marking a diverse array of materials. It is particularly useful for applying identification marks, QR codes, logos, and other designs to products, and is commonly employed in industries requiring permanent marking.

Precious jewelry items and diamonds can also be laser marked with intricate detail. Additionally, machine parts, automotive components, textiles, ceramics, and various other materials can be efficiently marked using laser machines.

Types of Laser Marking

Laser Engraving

Laser engraving is a widely utilized method of laser marking, commonly employed for inscribing ID numbers, crafting sketches, logos, QR codes, and various other designs. While both laser engraving and laser marking are used to create permanent marks on various materials, they have key differences in terms of the depth, appearance, and applications of the resulting marks.

In the laser engraving process, material is removed from the surface, creating discernible depth and texture. This technique results in a 3D effect when viewed from specific angles, as well as a tactile sensation when touched. During engraving, laser beams elevate the surface temperature to the material's boiling point, causing it to melt and eventually evaporate. In some instances, the material may burn due to the intense heat, transforming into dust or debris.

On the other hand, laser marking, which includes techniques such as annealing and coloration, alters the material's surface properties. This process generally produces a shallower, smooth mark, with a color change or contrast visible on the surface. Laser marking is typically used for creating barcodes, serial numbers, or decorative patterns on materials like metals, plastics, and ceramics.

The engraved markings typically appear darker than the original material color, providing a long-lasting and durable result, thanks to the deep cuts. Laser engraving is particularly well-suited for materials such as wood, plastics, ceramics, and certain metals. When engraving metal, it is important to use a fiber laser with sufficient power to achieve the desired depth and 3D effect. Insufficient power may result in shallow markings, lacking the characteristic depth and texture of a proper engraving.

In contrast, laser marking is more suitable for applications requiring minimal surface disruption or when the material is sensitive to high heat. It is also preferable when a smooth, unaltered surface is desired, as the process does not create any depth or grooves in the material.

2. Laser Annealing

Laser annealing is a technique that uses a laser beam to heat metal slowly. This causes oxygen to diffuse below the surface of the metal and oxidize it from within. When the metal cools down, its color changes. This process is also referred to as heat marking and involves a laser beam applying a small amount of heat to the surface of an object, causing a thermo-chemical reaction .

While the most common color produced is black, adjustments to the laser's power settings can yield other colors such as red, yellow, and green. Unlike laser engraving, laser annealing does not create cuts or deep marks; instead, the marking is formed on the surface through oxidation, maintaining a smooth appearance. Laser annealing is predominantly employed on metals, particularly titanium, steel, iron, and other ferrous materials. It is widely used in various industries for metal marking, including medical, automotive, and aerospace sectors, due to its non-invasive and precise nature.

3. Laser Foaming

In the laser foaming method, the surface of the material is melted, leading to a phase change that generates gas bubbles. As these bubbles attempt to escape from the surface, they oxidize, creating an eye-catching foaming effect. The foamed bubbles exhibit a visually appealing appearance, characterized by a lighter color, light refraction, and a glittering effect. This combination of properties lends a distinctive and exceptional look to the marked material. Laser foaming is primarily suited for plastics, and it is not compatible with materials such as metals and wood. One notable advantage of this method is that the resulting bubble marks are lighter in color than the original material, making it particularly useful for marking dark plastics.

4. Laser Carbonizing

Carbon migration laser marking is a process that occurs in certain metals and alloys containing carbon. When laser beams are applied to the material, high temperatures cause the carbon molecules to migrate to the surface, where they form bonds with surface molecules, facilitated by the heat. As a result of this bonding, dark marks appear on the surface. This specific laser marking technique is applicable exclusively to metals containing carbon, such as steel, stainless steel, titanium, and numerous other metals and alloys. By leveraging the unique properties of carbon migration, it is possible to create durable, dark markings on these materials.

5. Laser Coloration

Laser beams can generate a range of colors on both metal and non-metal materials, depending on their composition and the laser's speed, power, and other specifications. For example, when laser beams are applied to a metal surface, such as stainless steel, different colors may appear based on the settings used. This phenomenon occurs due to the oxidation of molecules on the metal surface, allowing for the creation of multicolored marks. This technique is also effective for plastics, as the application of laser beams can result in the formation of bubbles. The color of these bubbles is influenced by the laser settings and the specific type of plastic used. Consequently, the desired colored mark can be achieved on the material.

To utilize this laser marking method effectively, it is essential to experiment with various settings on the laser machine. Through testing and adjustments, the optimal settings for achieving the desired color can be identified and applied.

Types of Laser Marking Machines

1. Infrared Lasers

Infrared lasers emit beams with a wavelength of 1064 nm, which falls within the infrared region and is invisible to the naked eye. However, this wavelength is easily absorbed by materials, making it an ideal choice for marking metals and plastics. These lasers are particularly well-suited for engraving materials such as plastic, aluminum, stainless steel, iron, gold, platinum, silver, and various other metals.

Specifically designed for marking and engraving, infrared lasers enable the achievement of outstanding results in a short amount of time. Handheld infrared laser machines are also available, offering increased versatility. These portable devices can create marks on objects of any size and position, such as marking a steel wall, for example. Infrared lasers are an affordable option for marking metals, as fiber lasers tend to be more expensive. Additionally, they operate at a faster pace when combined with the galvo system, making them a preferable choice if your primary focus is on marking plastics or metals.

2. Diode Lasers

Diode lasers are among the most affordable options for laser marking, engraving, and cutting machines, making them an ideal choice for starting a small business with minimal investment.

Diode laser machines are suitable for marking materials such as wood, acrylic, leather, plywood, glass, ceramics, stainless steel, copper, and certain other metals. However, it is crucial to ensure that the machine's power is sufficient for working with metals in order to achieve exceptional results. Typically, diode laser machines have an open design. Many machines offer adjustable height risers and compatibility with rotary attachments, adding to their versatility. Additionally, they often feature a larger engraving area compared to most desktop laser machines.

3. CO2 Lasers

CO2 lasers are powerful desktop devices capable of cutting, engraving, and marking materials swiftly and efficiently. They utilize a CO2 tube to generate laser beams through a combination of gases.

With a CO2 laser, you can work on materials such as wood, plywood, acrylic, ceramics, leather, plastics, rubber, and some metals. These machines typically feature an enclosed design, making them safe for home use and ideal for starting a small laser marking business. CO2 laser machines tend to be faster and more expensive than diode laser machines, due in part to their advanced technology and impressive power output. However, they also offer valuable features like built-in cameras, contributing to their overall efficiency and utility.

4. Fiber Lasers

When it comes to marking metals, fiber laser machines are the top choice. If you have the budget and your primary focus is on marking metals, a fiber laser is the ideal investment. This is because the wavelength of these lasers is easily absorbed by metals, and they are specifically designed for tasks such as marking, cutting, cleaning, engraving, and welding metals. You can obtain a suitable machine tailored for marking or engraving purposes. Fiber laser machines enable you to mark virtually all metals at an outstanding speed, surpassing the capabilities of CO2 or diode lasers. With a fiber laser, you can complete markings within a matter of seconds, greatly enhancing productivity and efficiency.

Factors to Consider When Buying a Laser Marking Machine

While buying a laser machine, you must consider some important factors that will help you select the right machine according to your requirements. All machines have different specifications, so you have to decide which one is perfect for you.

1. Type of the Material

The first factor to consider when selecting a laser marking machine is the type of material you want to mark. If you primarily work with wood, a diode laser will deliver exceptional results at a lower cost. Diode and CO2 lasers are highly effective for non-metals, including wood, acrylic, rubber, ceramics, glass, and more. For marking metals, a fiber laser is the ideal choice, although diode and CO2 lasers can also be used for marking metals. If you mostly work with non-metals but occasionally mark metals, opt for a higher-powered diode laser. However, if your primary focus is marking metals, an infrared or fiber laser will best meet your needs.

2. Size and Shape of the Product

All laser machines have a limited working area, which constrains the size and shape of objects that can be processed. It's essential to examine the size of the workspace to understand the scope of items that can be marked. Desktop laser machines, though compact, generally provide ample working space for most tasks. Some machines even offer extensions, allowing for an increase in the work area.

Flat objects can be engraved directly using a laser machine. However, cylindrical and spherical objects require rotary attachments to rotate the object during marking. Ensure that your machine is compatible with these attachments.

For example, if you want to mark a baseball, you will need a suitable rotary attachment designed for rotating spheres. Similarly, to mark baseball bats, you will need a compatible attachment for cylindrical objects. Keep in mind that these attachments also have limitations regarding object size, shape, and diameter.

3. Power and Speed Requirement

The maximum optical power that a laser machine can deliver is crucial, as it determines whether the machine can effectively mark the desired material. For instance, low-power diode lasers may struggle to mark metals, but with a power range of 20W to 40W, they can achieve excellent results. For marking wood, low optical power is often sufficient; however, marking metals requires higher power. It's essential to check the machine's optical power before purchasing.

Many people confuse electric power with optical power. There are three types of power associated with a laser machine: machine power, which refers to the electrical consumption of the machine; electrical power of the module, which indicates electrical consumption; and optical power, which indicates the power of the laser beams. Focus on the optical power when considering a machine.

Optical power values are typically lower compared to the other two types. Some companies may not mention optical power, leading buyers to assume that the machine is more powerful by looking at the electrical power. To avoid misconceptions, always consider optical power when making a decision.

4. Accuracy and Precision

Quality of marking is crucial, and all laser machines have limitations in terms of accuracy and precision. Insufficient accuracy can result in overlapping marks and subpar logo sketches. Thus, it is essential to consider the accuracy of the machine to ensure high-quality vector engraving/marking. Some desktop machines offer remarkable accuracy. For example, the xTool F1 boasts an engraving accuracy of 0.00199mm. With this level of precision, you can expect error-free vector engraving.

5. Upfront Cost and Maintenance

When purchasing a laser marking machine, consider your budget as well. For an affordable option with minimal maintenance, a diode laser machine is a great choice. Prices for these machines typically range from $600 to $1,000, depending on the features. Another option is an infrared + diode laser machine, which may cost more but offers additional features and versatility in engraving a variety of materials.

CO2 laser machines are a more expensive alternative, with prices ranging from $3,000 to $6,000. These powerful machines can work on multiple materials, especially the non-metals.

Fiber lasers are the most expensive option, with prices starting at $10,000 and reaching over $100,000, depending on size and features. These machines are incredibly powerful and efficient, capable of marking or engraving all types of metals and a wide range of other materials in a short time.

6. Safety and Environmental Regulations

Safety is a crucial concern when working with lasers. Although laser machines are generally safe, it's essential to consider the safety features they offer.

Firstly, the machine should have a protective cover or lid to filter the laser beams, preventing potential harm to your eyes. Most machines are equipped with this safety feature.

Secondly, consider the exhaust system. While some machines are enclosed, if the one you're considering is open, it's advisable to get an enclosure. Laser machines emit fumes and particles that can contaminate the working area, so a proper exhaust system should be in place to safely expel the air.

Fire safety is another important factor. Laser machines should have warning systems, alarms, and emergency buttons to prevent accidents. Some machines are also compatible with fire kits that can extinguish a fire automatically without damaging the equipment.

Additionally, be mindful of environmental regulations. Directly expelling smoke and debris from the machine outside your home or workspace can pollute the environment. To address this, invest in an air purifier that will collect debris and purify the air. This ensures that the exhausted air is clean, preventing pollution in your working area and the surrounding environment.

Best Laser Marking Machine

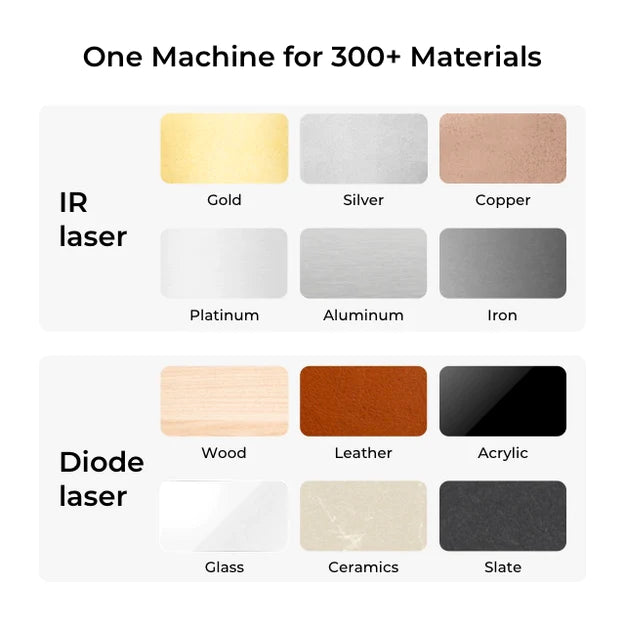

The xTool F1 is a unique combination of infrared and diode lasers, making it capable of working on a wide range of materials. With its 10W diode laser, it can engrave or mark wood, acrylic, glass, paper, leather, ceramics, rock, and more. It can also cut materials like wood, acrylic, and plywood. The infrared laser, on the other hand, is perfect for marking metals such as gold, silver, platinum, iron, stainless steel, aluminum, and plastics. This versatility makes it an ideal option for laser marking, as it covers almost all commonly used materials.

The xTool F1 boasts impressive speed and precision, with a maximum speed of 4,000mm/s and an accuracy of 0.00199mm even at high speeds. This ensures finely detailed graphics marking in a short amount of time.

As a handheld machine, the xTool F1 is portable and easy to use. Its compact design and exceptional features set it apart from other laser machines on the market. The machine can automatically adjust its focus, but manual adjustments are also possible. It offers a preview of the design before marking, which aids in accurate laser positioning.

Safety features are top-notch in the xTool F1. Its enclosed design prevents smoke and particles from escaping, while the smoke purifier allows for indoor use without issues. The light-filtering lid enables users to observe the marking process while protecting their eyes from laser exposure.

The xTool F1 is compatible with the RA2 Pro, a 4-in-1 rotary attachment for marking cylindrical and spherical objects. This versatility allows the machine to handle a wide range of tasks.

Ease of use is another advantage of the xTool F1. Even without prior experience, users can quickly learn to operate the machine with just a few tutorials. The machine comes with native and free software (XCS), and it is also compatible with LightBurn.

In summary, the xTool F1 is an excellent choice for marking, engraving, and cutting. It is versatile, user-friendly, fast, accurate, and reasonably priced, making it an ideal solution for a side hustle, hobby, or small business. With the xTool F1, you can achieve perfection in your laser marking projects.

Laser Marking Best Practices

To achieve the best results with your laser marking projects, follow these best practices:

- Select the appropriate machine for the material: As previously discussed, choose a machine that is suitable for the specific material you will be working on, whether it's metals, wood, plastics, etc.

- Adjust the laser focus based on the material height: Properly adjusting the focus will ensure exceptional marking results.

- Conduct a power-speed test before starting: Use spare materials to determine the optimal settings for your project by testing the power and speed of the laser.

- Clean the surface before marking: Remove any oil, grease, or dust from the surface to ensure a clean and precise marking process.

- Adhere to safety precautions while using the machine: Wear protective goggles and never leave the machine unattended during operation to maintain a safe working environment.

Conclusion

Laser machines are ideal for marking different types of materials, including metals and non-metals. Using the machine, you can do the job with optimal accuracy and get exceptional results. We have discussed how you can choose the right machine for your needs. For your ease, we have shared xTool F1, which is an incredible combination of a diode and infrared laser to cover a wider range of materials. It is a special machine made for marking at a fast pace. Its exceptional features, safety, and technology are worth every penny you spend on it.

Related Articles

Laser Classification and Laser

Laser Classification and Laser Safety: Tips You Need to Know