Busy and cold winter has arrived! Perhaps you're searching for a guide on safe and clean laser processing, and so we're here. Generally, there are two ways to ensure fresh air during laser processing.

In This Article

- How to Achieve Fresh Air during Laser Cutting and Engraving?

- How to Choose between an Air Purifier and an Exhaust Fan?

- How to Use the Air Purifier or Exhaust Fan Correctly?

- Conclusion

How to Achieve Fresh Air during Laser Cutting and Engraving?

1. Use an Air Purifier

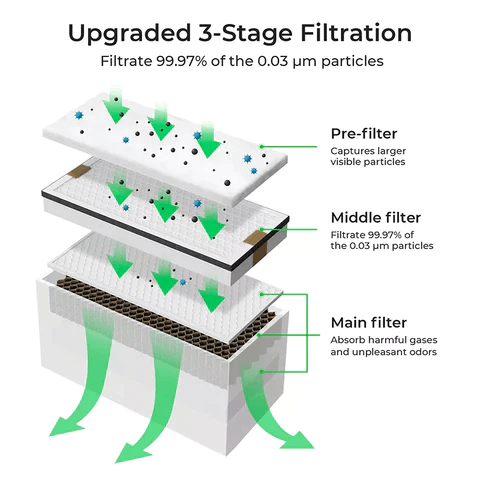

Choose air purifiers equipped with high-efficiency carbon fiber or HEPA filters. These filters effectively capture smoke and particles, purifying the air. Using an air purifier can reduce odors, allowing you to breathe confidently. However, for materials like acrylic, some odor may still be present.

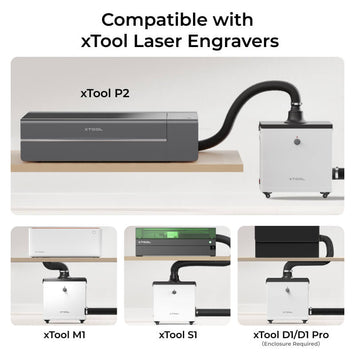

- For xTool P2, S1, M1, D1/D1 Pro(enclosure required), select the xTool Smoke Purifer.

- For xTool F1, opt for the xTool Desktop Air Purifier.

2. Get an Exhaust Fan

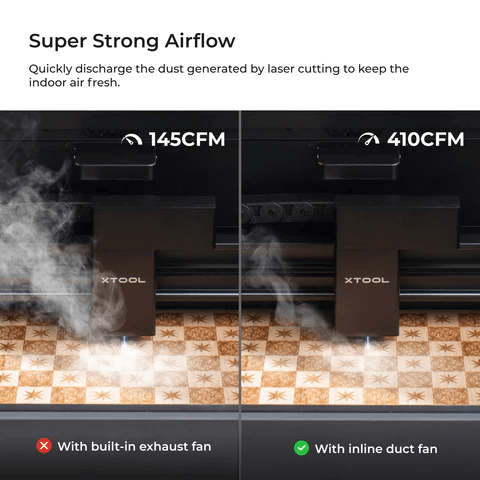

xTool enclosed laser machines(P2, S1, M1) typically come with a built-in exhaust fan that vent smoke out through exhaust pipes. You can also get a more powerful external fan for higher-efficiency exhaustion. For instance, the xTool 6-inch Inline Duct Fan provides 410 CFM airflow and is compatible with xTool P2, S1, M1, and D1/D1 Pro (enclosure required).

How to Choose between an Air Purifier and an Exhaust Fan?

Why Choose Air Purifiers

An air purifier is ideal for indoor use, especially during cold winters, as they do not require opening windows or creating holes in walls. The

- For xTool P2, S1, M1, D1/D1 Pro(enclosure required), select the

xTool Smoke Purifer . - For xTool F1, opt for the

xTool Desktop Air Purifier .

Why Choose Exhaust Fans

An exhaust fan offers better smoke exhaust performance but require an outdoor access, which may not be suitable in winter unless you have an exhaust hole in your wall. If outdoor venting isn't an option, consider using a fan.

Attention: Ensure the external fan has a larger airflow than the built-in one of your laser machine or it will only waste your money. The xTool 6-inch fan is a wise choice with powerful 410 CFM.

How to Use the Air Purifier or Exhaust Fan Correctly?

1. Replace/Clean the Filter Regularly

Regularly check the filters of air purifiers to maintain purification efficiency, especially the pre-filter, which can become clogged with frequent use.

The pre-filter can be washed for reuse. However, repeated cleaning may reduce its long-term filtering performance. The xTool Smoke Purifier offers another pre-filter for backup. If you find the purifier doesn't work well, wash the pre-filter and let it dry before using it again.

You can also get the Filter Replacement Kit for xTool Smoke Purifier.

For xTool F1 Desktop Purifier, please choose the special one.

2. Clean the Built-in/External Exhaust Fan Regularly

Both the built-in and external fans should be cleaned periodically to prevent blockages and maintain efficiency.

Here are some instructions about how to clean or replace the fan of xTool S1, P2, and M1.

- For S1: https://youtu.be/qoNVQFjLj1c

- For P2: https://youtu.be/YGeO0P26P7I

- For M1: https://youtu.be/GO5KUXuoKWw

3. Install and Use the Purifier/Exhaust Fan Correctly

Reduce the bend

Minimize bends in the exhaust pipe, as excessive bends can significantly reduce efficiency, even with an 8'' fan, it might perform like a 4'' fan if there are too many bends.

Let the built-in fan run longer

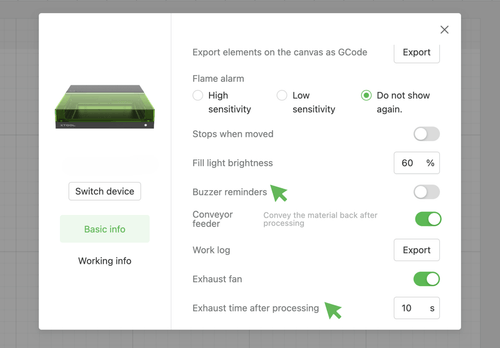

After processing, allow the built-in fan to run for a period to ensure thorough smoke evacuation.You can set your own exhausting time for xTool M1, S1, P2 in XCS software.[Image]

Install the external fan correctly

Ensure the correct installation of an external fan to prevent smoke from flowing back into the machine.For xTool Inline Duct Fan, you can install it according to the Airflow direction indicator on the product or refer to instructional videos.

Avoid using the purifier and the external exhaust fan simultaneously

Combining these two may not be effective because the high airflow from the fan can disrupt the air purification process, reducing its effectiveness.

Conclusion

Everything you need to know about dealing with smoke during laser working has been listed above. With the right approach, you can maintain a safe and fresh working environment for your laser cutter projects throughout the winter season.