Glass etching is a fascinating art form that has been around for centuries, allowing artists and hobbyists alike to create stunning designs on various glass surfaces. With the advent of modern technology, laser etching has emerged as a powerful tool for achieving intricate, precise, and consistent results. If you're looking to explore the world of glass etching or improve your skills, you've come to the right place.

In this comprehensive guide, we'll delve into the process of laser etching glass, discussing the advantages it offers over traditional methods, and providing step-by-step instructions for achieving beautiful glass etching results. We'll also cover a range of creative ideas and inspirations to get your creative juices flowing and help you choose the best laser etching glass machine for your needs. Whether you're a seasoned professional or a curious beginner, this guide will equip you with the knowledge and techniques you need to master the art of laser etching glass. Let's get started!

In This Article

- What is Glass Etching?

- Advantages of Laser Etching and Engraving Glass

- How to Laser Etch/Engrave Glass: A Step-by-Step Guide

- Inspiring Ideas for Glass Etching and Engraving

- Revolutionize Your Glass Etching Projects with the xTool P2 Laser Engraver

- FAQs of Laser Etching/Engraving Glass

- Conclusion

What is Glass Etching?

Glass etching is the process of creating decorative designs, patterns, or images on the surface of glass by removing a small amount of material. Various techniques have been developed to etch glass, ranging from traditional to modern methods.

Traditional glass etching methods include:

- Acid etching: Involves the use of hydrofluoric acid to dissolve the surface of the glass, creating a frosted appearance. This method can be dangerous due to the highly corrosive nature of the acid.

- Sandblasting: Requires the use of high-pressure air to propel abrasive materials like sand or silicon carbide against the glass surface, resulting in a rough, frosted texture. Sandblasting offers more control over the depth and appearance of the etching but can be messy and requires specialized equipment.

- Glass etching cream: A more accessible and safer alternative to acid etching, glass etching cream contains a mixture of chemicals that react with the glass surface to create a frosted appearance. This method is popular among DIY enthusiasts and hobbyists as it can be easily applied with a brush or stencil and requires minimal equipment.

Modern glass etching techniques have evolved with the advent of advanced technology, leading to the introduction of laser etching and engraving. Laser etching and laser engraving utilize a focused beam of light to remove a small amount of material from the glass surface, creating a precise and intricate design. The terms "etching" and "engraving" are often used interchangeably, but they differ slightly in the depth of the mark made on the glass. Etching is generally shallower, while engraving creates deeper marks. Laser etching and engraving have rapidly gained popularity due to their unparalleled precision, consistency, and efficiency.

Advantages of Laser Etching and Engraving Glass

Laser etching and engraving offer several advantages over traditional glass etching methods, making it a popular choice among artists, professionals, and hobbyists. Here are some of the key benefits of using lasers for glass etching:

- Precision and detail: Laser engravers are capable of producing incredibly intricate and detailed designs on glass surfaces. The focused laser beam is precisely controlled by a computer-guided system, often referred to as a CNC (Computer Numerical Control) system. This system translates digital designs into a set of coordinated movements for the laser, allowing it to follow the desired path on the glass surface with extreme accuracy. The laser's fine beam, combined with the precise movements directed by the CNC system, enables users to create complex patterns, images, and text that may be difficult or impossible to achieve with traditional etching methods. Furthermore, the user can adjust the laser's settings, such as power and speed, to achieve different effects, offering unparalleled control over the etching process.

- Consistency in reproducing designs: As mentioned above, laser etching machines are computer-controlled, which means that designs can be easily replicated with exact precision, making them ideal for producing multiple identical pieces or large-scale projects.

- Speed and efficiency: The laser etching process is typically faster than traditional methods, as the laser beam can move rapidly across the glass surface. This is made possible by the computer-guided system (CNC) that directs the laser head's movement. The CNC system can translate digital designs into real-time, coordinated movements at high speeds, allowing the laser to quickly trace the intended design on the glass. As the laser's movement is not limited by the physical constraints that manual methods or even sandblasting may face, it can achieve higher speeds and smoothly transition between different parts of the design. This allows for shorter production times and higher output, especially when working with multiple pieces or large-scale projects.

- Minimal material waste: Since laser etching and engraving remove only a small amount of material from the glass surface, there is minimal waste generated during the process. This makes it an environmentally friendly option compared to methods like sandblasting, which can produce a significant amount of dust and debris.

- Environmentally friendly process: Unlike acid etching and glass etching creams, laser etching does not involve the use of harmful chemicals. This makes it a more environmentally friendly option, as there is no need to worry about chemical disposal or potential damage to the surrounding environment.

By choosing to etch glass with a laser, you can enjoy the benefits of precision, consistency, speed, and minimal environmental impact.

How to Laser Etch/Engrave Glass: A Step-by-Step Guide

Before diving into the step-by-step process, it's essential to understand the types of laser engravers that can etch and engrave glass. The most common type of laser engraver used for glass etching is the CO2 laser engraver. This type of laser utilizes a gas mixture, primarily containing carbon dioxide, which is excited by an electrical current to produce a laser beam. CO2 lasers are widely used for etching and engraving various materials, including glass, wood, acrylic, and more. They work by producing an infrared beam, which is absorbed by glass and causes the material to vaporize, resulting in the engraved design.

Steps for etching/engraving glass with a CO2 laser engraver:

Step 1: Preparing the glass

Select the right type of glass: Ensure that the glass you choose is compatible with laser etching/engraving. Flat glass, such as window panes or glass sheets, works well, as do cylindrical objects like wine glasses and bottles when using a rotary attachment.

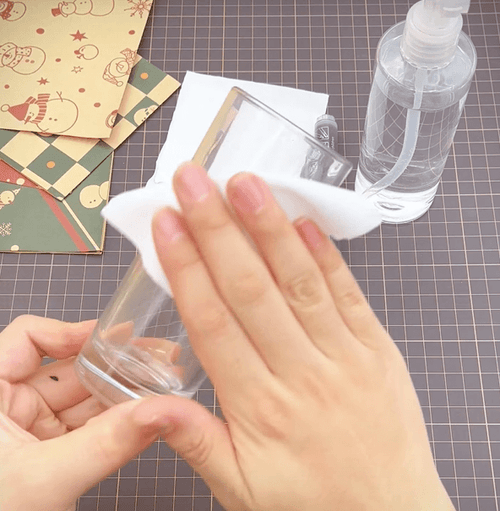

Clean the glass surface: Thoroughly clean the glass surface to remove any dust, dirt, or fingerprints that might interfere with the etching process. Use a glass cleaner and a lint-free cloth for best results.

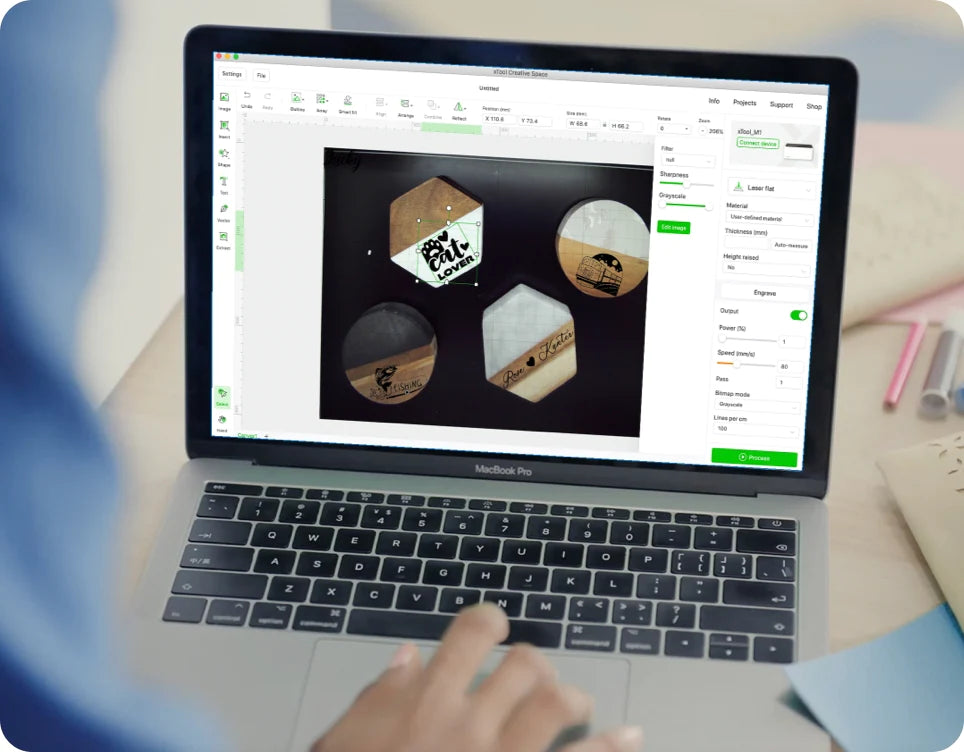

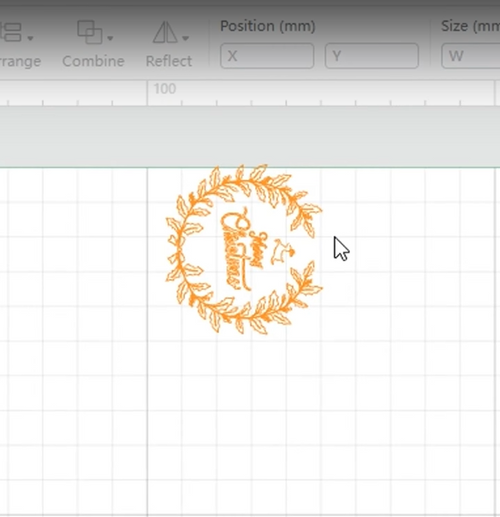

Step 2: Design creation and import

Create your design using graphic design software compatible with your laser engraver, such as Adobe Illustrator, CorelDRAW, or Inkscape to create your design or import an existing image. Save your design in a compatible file format, like SVG or DXF, and import it into the laser engraver software.

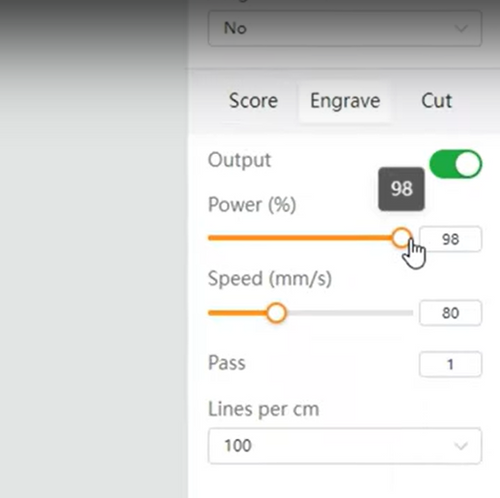

Step 3: Choosing the right laser settings

Power: Determine the appropriate laser power for the type of glass and the desired etching depth. Lower power settings will result in shallower etching, while higher power settings will create deeper engravings.

Speed: Adjust the speed at which the laser moves across the glass surface. Slower speeds can lead to deeper etching, while faster speeds will yield shallower results.

Step 4: Safety precautions

Protective gear: Wear appropriate protective gear, such as laser safety goggles, to shield your eyes from the laser beam.

Ventilation: Ensure that the workspace is well-ventilated to dissipate any fumes or smoke generated during the etching process.

Step 5: The etching/engraving process

Position the glass: Place the glass on the laser engraver's worktable or attach it to the rotary attachment, ensuring that it is secure and correctly aligned with the laser.

Focus the laser: Adjust the height of the laser head to bring it into focus with the glass surface. This step is crucial for achieving clean, sharp etching lines.

Start the etching process: Once everything is set up and ready, start the laser etching/engraving process by activating the laser engraver. Monitor the process to ensure that the design is being etched correctly and make any necessary adjustments to the settings as needed.

Step 6: Step 6: Post-etching/engraving cleanup and finishing touches

Remove the glass: Carefully remove the glass from the laser engraver once the etching process is complete.

Clean the etched surface: Wipe the etched surface with a damp cloth to remove any residual dust or debris from the etching process. If necessary, use a mild glass cleaner for a thorough clean.

Inspect the results: Examine the etched design to ensure that it meets your desired outcome. If needed, make adjustments to the design or laser settings and re-etch the glass to achieve the desired results.

Diode laser engravers can also effectively etch or engrave glass, offering an alternative to CO2 laser engravers. Diode lasers are generally more compact and budget-friendly, making them an appealing choice for hobbyists and small businesses looking to explore glass etching without a significant upfront investment.However, diode lasers require an additional pretreatment step for the glass, as their wavelength is not readily absorbed by the glass surface. This pretreatment process typically involves applying a specialized coating or film to the glass, which helps the diode laser to effectively etch or engrave the surface. To learn how to etch glass using a diode laser, follow this comprehensive guide that covers the necessary pretreatment steps and provides expert tips for achieving the best results.

Inspiring Ideas for Glass Etching and Engraving

Laser etching and engraving open up a world of creative possibilities for transforming ordinary glass items into personalized and unique works of art. Whether you're a professional artist, a small business owner, or a DIY enthusiast, here are some inspiring ideas for laser etching and engraving glass:

Personalized glassware

Create custom wine glasses, champagne flutes, or beer mugs with personalized designs, such as monograms, logos, or meaningful quotes. These make great gifts for weddings, anniversaries, or housewarming parties.

Decorative mirrors

image credit: by DeriveHome via Etsy

Enhance the beauty of mirrors by etching intricate patterns or artistic designs around the border or directly onto the mirror surface. This can add a touch of elegance to any home décor.

Glass awards and trophies

image credit: by sofiasfindings via Etsy

Design and produce unique glass awards and trophies for corporate events, sports competitions, or academic achievements. Incorporate company logos, event details, and recipient names for a truly personalized memento.

Glass photo frames

image credit: by 28Collective via Etsy

Engrave decorative borders, patterns, or meaningful quotes onto glass photo frames to give them a personal touch. These make thoughtful and memorable gifts for friends and family.

Glass jewelry

image credit: by 3DLaserGifts via Etsy

Create one-of-a-kind glass pendants, earrings, or bracelets by etching intricate designs or images onto small glass pieces. This can be a great opportunity to showcase your creativity and artistic skills.

Glass ornaments

Design and produce custom glass ornaments for holidays, special occasions, or home décor. Etch seasonal designs, personal messages, or intricate patterns to create a unique and eye-catching decoration.

Revolutionize Your Glass Etching Projects with the xTool P2 Laser Engraver

The xTool P2 is a groundbreaking CO2 laser machine that brings advanced features and capabilities to the world of glass etching. Designed with laser enthusiasts and professionals in mind, this desktop laser machine offers a futuristic experience that will take your glass etching projects to new heights. Let's explore the exceptional features of the xTool P2 and how they make it the perfect choice for glass etching.

Extensive Material Compatibility

The xTool P2 is compatible with a wide range of materials, including glass. Unlike other laser machines, the xTool P2 doesn't require spray paint or marking paper for glass engraving. Instead, you can directly etch the glass surface, saving time and effort.

Impressive Power for Speedy Glass Etching

With its 55W of immense power, the xTool P2 can etch glass quickly and efficiently. The machine operates 6-12 times faster than most diode laser machines on the market, with a maximum engraving speed of up to 600 mm/s. This increased speed allows you to complete your glass etching projects faster than ever before.

Smart Cameras for Precision and Ease of Use

The xTool P2 features two 16MP smart cameras that provide a live preview of the work area, making it easy to position your designs accurately on the glass surface. The cameras also enable the machine to focus the laser automatically, taking into account the height and type of material being used.

Curved Surfaces Engraving and 360-Degree Cylindrical Glass Engraving Made Possible

One of the standout features of the xTool P2 is its ability to engrave curved surfaces. The machine can automatically construct 3D models of objects and adjust the laser's focus accordingly, allowing you to etch curved glass with unparalleled accuracy. The xTool P2 can also engrave cylindrical and spherical glass objects like wine glasses, champagne flutes, or beer mugs using the compatible xTool RA2 Pro rotary attachment.

Large Working Area and Automatic Passthrough for Versatility

The xTool P2 boasts a large working area (23.6'' x 12.1''), making it suitable for a wide range of glass etching projects. Additionally, its automatic passthrough feature eliminates restrictions on the length of the object being etched, so you can work on glass pieces of any size.

Safety Features to Protect Users and Workspace

The xTool P2 prioritizes safety with features like an enclosed design, light-filtering lid, an automatic lock on the lid, and an emergency button. Additionally, the machine offers exception warnings to alert users to potential issues and an optional fire safety kit for added protection.

In summary, the xTool P2 is an innovative and feature-rich CO2 laser machine that can transform your glass etching projects. With its powerful performance, precision, versatility, and safety features, it's the ideal choice for anyone looking to take their glass etching skills to the next level.

Buy xTool P2FAQs of Laser Etching/Engraving Glass

Q1: What type of laser engraver is best for etching/engraving glass?

CO2 laser engravers are most commonly used for etching glass. Diode laser engravers can also be used, but they may require additional pre-treatment of the glass surface.

Q2: Can all types of glass be laser etched/engraved?

Most types of glass can be laser-etched, including float glass, crystal glass, colored glass, and glass mirrors. However, some types of glass, such as tempered glass, are not suitable for laser etching as they may shatter during the process.

Q3: Do I need to use any special coatings or treatments on the glass before laser etching/engraving?

For CO2 laser engravers, you can directly etch onto the glass without any special coatings or treatments. However, with diode laser engravers, you may need to apply a pre-treatment, such as a specialized coating, to ensure proper absorption of the laser.

Q4: Can you wash laser etched/engraved glass?

Yes, laser-etched glass is wash safe as the etching process creates a permanent design on the glass surface that is resistant to wear and tear.

Q5: How deep is the etching on the glass?

Laser etching on glass is typically a surface-level process that creates a shallow, frosted appearance. The depth of the etching can vary depending on the power and speed settings of the laser engraver, as well as the type of glass being used.

Q6: Can laser-etched glass be repaired or removed?

Laser etching is a permanent process, and the design cannot be removed or repaired once it has been etched onto the glass surface.

Q7: Can I etch glass that is curved or has an irregular shape?

Yes, it is possible to etch curved or irregularly shaped glass, although it may require special equipment or attachments, such as a rotary attachment, to accommodate the shape and ensure a consistent etching result.

Q8: What is the ideal power and speed setting for laser etching glass?

The ideal power and speed settings for laser etching glass can vary depending on the type of glass, the thickness, and the specific laser engraver being used. It is recommended to consult the manufacturer's guidelines or perform test etchings on scrap pieces of glass to determine the best settings for your project.

Conclusion

Laser etching glass is a versatile, precise, and efficient method for creating custom designs and personalizing various glass items. With numerous advantages over traditional methods, laser etching allows for intricate patterns, quick processing times, and minimal damage to the glass surface. By choosing the right equipment, understanding the process, and exploring creative design ideas, you can elevate your glass etching projects and create stunning pieces of art or functional items for personal or commercial use. Remember to always prioritize safety and follow the guidelines provided by the laser engraver manufacturer. With practice and experimentation, you'll be well on your way to mastering the art of laser etching glass.

Related Articles

How to Make A Stencil?

Laser Cut Art: Top 10 Projects to Elevate Interiors