When it comes to buying the best laser cutters for your hobby or crafting business, you are always offered tons of choices. Each laser cutting machine model comes with its own set of features and capabilities that can boost your business. To facilitate your decision making in buying a laser cutter, we have picked some of the best ones in the market for you to choose from, including the machines from xTool, Glowforge and some other brands.

In This Article

- What is a Laser Cutting Machine?

- What is a Laser Cutter Used For?

- 10 Top Laser Cutters

- Laser Cutter FAQs

- Conclusion

10 Laser Cutters for Small Business and Hobby

Overall Review

| Laser Cutters | Best Overall | Best Value | Best for Small Business | Best for Speed | Best for Beginners |

|---|---|---|---|---|---|

| xTool D1 Pro 20W | ✔ | ✔ | |||

| xTool P2 | ✔ | ✔ | |||

| xTool F1 | ✔ | ||||

| FLUX Beamo 30W | |||||

| Ortur Laser Master 2 Pro S2 | |||||

| OMTech 40W | |||||

| Atomstack A5 | |||||

| Glowforge Pro | ✔ | ||||

| FSL Muse Core 40W | |||||

| TEN-HIGH 40W |

1. xTool D1 Pro Laser Cutter and Engraver

If you are looking for the best diode laser engraver for small business, xTool D1 pro could be a perfect choice. The quality, high accuracy, and dozens of other features make it an exceptional laser cutting and engraving machine. It is ideal for small businesses, hobbyists, DIY enthusiasts, designers, artists, and professionals.

xTool D1 Pro is a compact version of an industrial high-power diode laser engraver. It is compact enough to be placed over a table. It is made of robust materials that increase its life span and ensure high precision and accuracy.

It is available at a very reasonable price and can also be bought with affirm, starting at $75/month. Thus, it is the best budget laser engraver that small businesses and startups can easily afford.

Features:

- Multiple Power-level Laser Modules: The first advantage of xTool D1 Pro is that the laser module can be changed. There are four modules available, 5W, 10W, 20W and 40W. Buyers can easily select a suitable laser module for their needs.

- Most Power Module: The 40W xTool D1 Pro is the world's most powerful diode laser engraver. The powerful laser cuts 15mm plywood and black acrylic in only one pass. Besides, it can only cut other materials such as leather, MDF and felt efficiently.

- Powerful Laser Beam: It utilizes the latest laser compression technology to combine multiple laser beams into a highly-focused laser beam, making it more powerful.

- High Accuracy: The accuracy of xTool D1 Pro is more than amazing. The movement accuracy reaches 0.01mm because of the industrial-grade design, and the laser is also ultra-fine and highly focused at a single spot of 0.06*0.06mm(5W), making it ideal for engraving where highly precise details are required.

- Long Lifespan: The ALL-STEEL wheel and shaft are three times longer life than plastic wheels. It supports more than 100,000 slides.

- Large Engraving Area: The engraving area is also large enough to engrave or cut a piece larger than an A3 paper. Moreover, with the help of the extension, the working area is larger. In additon, combined with rotary attachment, it can be used for rotary engraving to engrave 90% regular and irregular cylindrical objects.

- Adjustable Height: The height of the tool can also be increased using risers. You can buy the number of risers you need and increase the height of the machine. One set of risers can increase the height to 70mm.

- Easy to Use: The software is pretty easy to use. It is compatible with xTool creative space and Lightburn. In addition, users can easily transfer data using Wi-Fi, USB cable, and TF card.

2. xTool P2 CO2 Laser Cutter

xTool P2 is a commendable CO2 laser cutting machine for small business. It offers a powerful 55W laser that can cut through a wide range of materials rapidly, for example, it can through 18mm black walnut and 20mm acrylic in one pass. Combined with its smart design and versatiltiy, it is a great choice for those looking to take their businesses to the next level.

Features:

- Improved productivity: With a maximum engraving speed of up to 600mm/s and the ability to engrave all objects of the same shape in the engraving area with the help of smart cameras, xTool P2 allows you to fulfill more orders in a day, leading to a higher income. CO2 laser cutters typically work faster than diode laser cutter, so if you have already own a diode laser, you can invest in a CO2 laser to boost your productivity.

- Live Preview & Auto-focus: xTool P2 has two cameras that provide a live preview of the working area and autofocus functionality, allowing you to drag and drop your design on the material to be processed accurately, thus reducing material waste and ensuring hight quality outcomes.

- Automatic Passthrough: This feature is particularly beneficial for large projects. The material is put into the passthrough slot and released from the other side, eliminating length restrictions. You can even combine it with the automatic conveyor to feed materials automatically. This allows you to meet diverse market demands.

- Engraving Curved Surfaces: Thanks to the ability to construct 3D models of objects, the xTool P2 can accurately engrave on curved surfaces. This allows small businesses to offer unique, customized products that sell higher prices.

- 360 Degree Cylindrical Engraving: Attached the rotary attachement, xTool P2 can engrave cylindrical objects including tumblers, cups, mugs, rings, rolling pins and more. This further diversify small businesses' product offering.

- Large Working Area: With its spacious bed size (26.7''×14.1'') and processing area (23.6''×12.1'') , the xTool P2 can accommodate larger projects. And the passthrough and riser base features further improve its working area, making it ideal for businesses that work on large-scale or batch orders. This feature not only enhances productivity but also allows businesses to take on a greater variety of orders.

- Extensive Material Compatibility: The xTool P2's CO2 laser allows small businesses to work on a wide range of materials, including metals and non-metals. It is worth mentioning that it can cut and engrave acrylic of all colors, both opaque and transparent, compared to diode laser cutters, which can only process some opaque acrylic. This versatility allows businesses to diversify their product offerings, catering to a broader customer base and different market segments.

- Incredible Safety Features: Safety is a critical aspect in any business operation, and the xTool P2 has brilliant safety features, including a completely enclosed design, an emergency shut-off button, exception warnings, and a dediated fire safety set and smoke purifier, minimizing the risk of accidents and ensuring a safe workspace.

- Compatibility with Advanced Accessories: xTool P2 is compatible with various accessories including rotary attachment, automatic conveyor feeder, riser base, smoke purifier and fire safety set, adding new functionalities and catering to specific project needs. This flexibility is ideal for small businesses that need to adapt to changing customer demands or market trends.

3. xTool F1 Portable Laser Engraver

The xTool F1 stands out as a game-changer in the realm of portable laser engraver for small business, bringing industrial-grade technology experience with an affordable price.

Features:

- Super Fast and Accurate: Thanks to advanced industrial-grade galvo laser technology, xTool F1 achieves an impressive engraving speed of up to 4,000m/s. This remarkable speed, nearly equivalent to high-priced fiber lasers, drastically reduces engraving time, improving productivity. xTool F1 also offers an astounding 0.00199mm accuracy, significantly outperforming other similar laser engravers on the market. This accuracy allows small businesses to provide their customers with flawless results, reinforcing their reputation for quality.

- Handheld and Portable: The compact, handheld design of xTool F1 allows it to be used anytime, anywhere. Its ability to function as both a handheld and desktop laser engraver increases its utility and adaptability, making it an invaluable tool for businesses that require on-the-go engraving or for engraving various sizes and angles. It also works with the xTool Creative Space software, which is compatible with various operating systems, including Windows, macOS, iPadOS, iOS, and Android. This ensures that you can operate the machine from your preferred device, whether you're in the office or on-site at a client's location.

- Dual Laser System: xTool F1 is equipped with both a 10W diode laser and a 2W infrared laser, enabling it to engrave/cut a wide variety of materials. The diode laser works effectively on materials such as wood, leather, acrylic, glass, ceramics, rubber, fabric, slate, etc., while the IR laser can handle common metals and plastics, including gold, silver, platinum, copper, aluminum, iron, and more. This expands the range of potential laser engraving projects, allowing small businesses to cater to a broader array of customer needs.

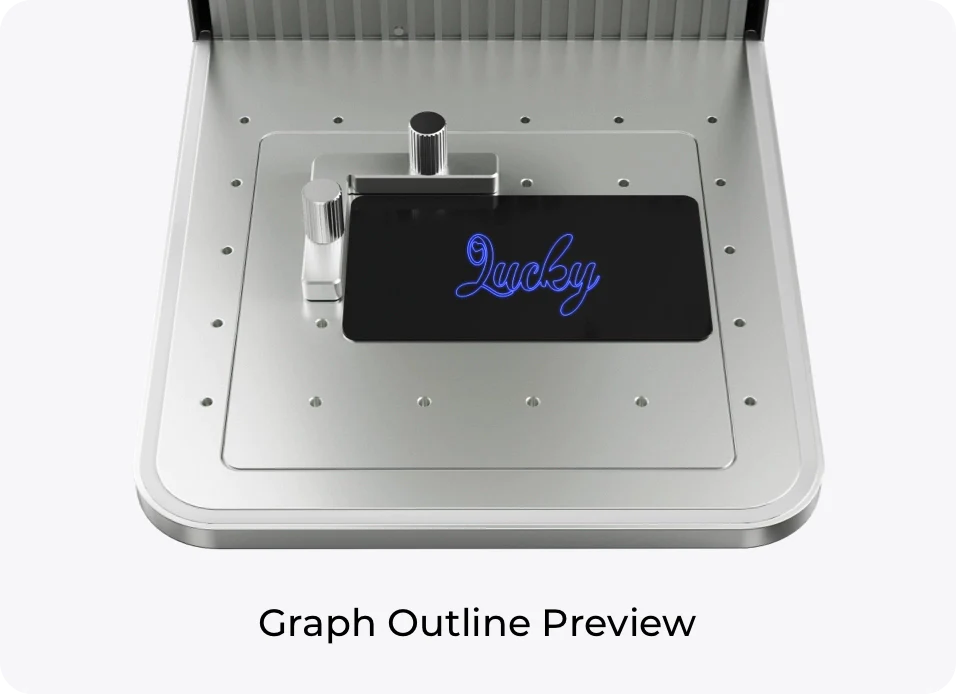

- Live Engraving Preview: With the xTool F1, you can preview your design on the object before engraving. This helps prevent wasted materials and ensures the final product meets the customer's expectations. The preview is also incredibly fast, with speeds of up to 10,000 mm/s.

- Auto Focus: Operating the machine is also simple: just place the object in the engraving area, enter the thickness of the material into the laser engraver software, and the machine automatically focusing the laser head.

- Safe Design: xTool F1 is designed with the user's safety in mind. The laser is fully enclosed to prevent laser beams and debris from escaping, protecting the user's eyes and hands. It also includes a built-in fan to extract smoke and smell. For additional safety and to prevent indoor pollution, a desktop smoke purifier can be attached to the machine.

- Rotary Attachment Compatibility: xTool F1 is capable of engraving cylindrical objects by attaching the RA2 Pro, a 4-in-1 rotary attachment that can engrave 90% of irregular objects. This expands the range of products that a business can offer. The machine's cover can be adjusted at any position, ensuring that attaching the rotary is not a problem.

4. Glowforge Pro CO2 Laser Cutter

Glowforge Pro is one of the high-end desktop CO2 laser cutting machines. It is a compact machine packed with a wide range of outstanding features.

image credit: Glowforge

The machine has a live camera preview that helps you see your design and the result before you start the engraving. It also helps in the accurate positioning of the design over the object. In addition, the height of the module or focus is adjusted automatically to offer high precision.

The high-resolution engraving of the machine is awesome. It gives the perfect 3D appearance and feel and supports 3D curves with 1,000 DPI resolution. In addition, the movement of the motors in the machine is more precise than a thousandth of an inch.

A distinct feature of the machine is that it does not require desktop software. It works on cloud-based software that you can use on your internet browser. Moreover, the software only requires dragging and dropping. It supports vector and raster graphics formats, including PNG, SVG, JPG, and PDF.

Features:

- The 45W CO2 laser tube is powerful enough to engrave materials at a very high speed. Glowforge Pro has three times enhanced speed to complete the job quickly.

- It supports hundreds of materials that allow the user to make a wide variety of products.

- The machine is compatible with Mac, PC, Android, and iOS.

- The autofocus makes engraving easier for beginners.

5. Ortur Laser Master 2 Pro S2 Laser Cutter

Ortur Laser Master 2 Pro S2 is undoubtedly an amazing laser engraver that has won the hearts of users. Firstly, the speed of the machine is outstanding. It engraves almost two times faster than similar machines on the market. The fast speed due to the latest firmware optimizes the motion algorithm and offers a maximum speed of 15,000mm per minute.

image credit: Ortur

The machine is full of safety features. First of all, there is an emergency stop button and a flame detector alarm. Additionally, it contains position deviation protection, excess exposure detection, laser beam safety, and power control. All these features make the machine suitable for beginners.

There are four options for the buyer to choose the laser module. All modules have different optical power and focal spot dimension. The user can choose a suitable module for engraving. The highly focused laser module has focal spot dimensions of 0.07 x 0.06mm, which is ideal for fine details during engraving.

The accessories and attachments, such as Air Assist, Air Flow Regulator, z-axis lifting device, roller rotary, and enclosure casing, are also available.

Features:

- The machine is made of sheet metal and aluminum, which makes it durable and stable.

- It comes with a flexible chain cable that does not break during operation.

- The users can choose the right module, considering whether they need to prefer engraving, cutting, or both.

- The engraving area is 400 x 400 mm, which is large enough.

- It supports all commonly used file formats for laser machines.

6. OMTech 40W Laser Cutter and Engraver

This is a powerful 40W CO2 laser cutter. It is a compact desktop machine that can be used in homes and small offices.

image credit: OMtech

The control panel on the machine makes it easier for the user to control the laser and its operation. It also has a laser test switch and an emergency stop button. In addition, there is an LED display to show the power and temperature of the laser tube. The power is easily adjusted using the control panel.

The machine is enclosed in a sturdy frame that provides a stable bed for the object. It also has a built-in exhaust fan and water-cooling system to keep the machine in optimal condition and deal with fumes and smells.

It shows a wider range of compatibility with software and file formats. It is compatible with CorelLaser and CorelDraw. Moreover, it supports TIF, JPG, JPEG, WMF, EMF, and PLT. It engraves a wide range of materials, including wood, glass, fabric, paper, fiberglass, acrylic, ceramic, plastic, anodized aluminum, mylar, and other types of non-metal materials.

Features:

- The machine is made of heavy-duty and quality materials to offer long life.

- The control panel is excellent for controlling the laser power and other things.

- It has a built-in cooling fan to remove harmful gasses, small, and smoke and ensure proper ventilation.

- There are detachable wheels to move the machines without lifting them.

- The engraving area is only 300 x 200 mm, which is not enough but suitable for a wide range of applications.

7. ATOMSTACK A5 Laser Cutter

ATOMSTACK A5 is a popular laser engraving tool among DIY lovers. It is a diode laser machine that can work on a wide range of materials. It can engrave on wood, paper, plastic, leather, bamboo, and lacquered metal and can cut cardboard, plastic board, wood, acrylic, and fabric.

image credit: Atomstack

The machine contains a protective glass on its laser module that protects your eyes from harmful rays. The module also has the autofocusing feature to focus correctly on the objects.

The engraving area is large, 410 x 400 mm, to work on a wide range of objects. Any object can be engraved with ultimate precision because of the fine laser spot and controlled movement of the motors. The engraving accuracy reaches 0.01mm, which is commendable.

The machine is compatible with Windows and Macs and supports different formats of graphics, including NC, JGP, BMP, DXF, and PNG.

Features:

- The structure is entirely made of metal to make the machine solid and stable. It can be assembled in 20 minutes.

- There is no need to adjust the focus of the laser machine. It has a high-power and autofocusing laser.

- It has a built-in cooling fan to remove harmful gasses, small, and smoke and ensure proper ventilation.

- Engraving can be done with high precision

- It works on LaserGRBL and LightBurn.

- The eye protection filters 97% UV light and protects your eyes without goggles.

8. FLUX Beamo 30W

This Flux Beamo is a CO2 laser in a compact design like a desktop printer. It has a 30W laser optical power to work on cardboard, wood, bamboo, leather, fabric, rubber, cement, acrylic, stone, stainless steel, and anode metal.

image credit: Flux

Surprisingly, an add-on is available that has a diode as well as a CO2 laser to improve the cutting speed and efficiency.

Users can use its desktop software on Windows, macOS, Chrome OS, and Linux, and the mobile application is for iOS and Android. Beginners can easily use these applications and get the job done without any hassle.

The high-resolution laser of 1,000 DPI offers small engraving width. It covers minute details during engraving at a depth of 0.05mm. Due to the presence of a built-in HD camera, the object can be seen on the software so that the design can be placed on the object easily.

The machine has a rare built-in feature of internal water cooling. The feature is only available in industrial machines, and it keeps the components at optimal temperature and increases the lifespan.

Features:

- The machine can cut materials up to 5mm thick.

- The compact and sleek design attracts the eye.

- It has a built-in cooling fan to remove harmful gasses, small, and smoke and ensure proper ventilation.

- It has a water-cooling feature to keep the temperature of components in the optimal range.

- There are various safety features, including emergency shutdown and open lid detection.

9. FSL Muse Core 40W CO2 Laser Cutter and Engraver

This is a massively powerful 40W CO2 laser engraver. The touchscreen LCD comes to attention in the first place. In addition, the internal LED lighting also illuminates the object so that the user can see it during engraving and laser cutting.

image credit: FSL

The machine is compatible with its own specialized software Retina Engrave V3.0. It is beginner-friendly and does not require any internet connection. The best part is that the software can design advanced vector trajectories, so you might not need other software all the time. You can also alter the existing or imported designs using the software.

An add-on called COOLBOX is an excellent accessory for the machine. It keeps the laser machine cool through air and water cooling. It also throws the fumes and smokes away.

The machine can work on hard as well as soft objects, such as wood, acrylic, leather, fabric, stone, and glass. It is an awesome machine for beginners as well as experts.

Features:

- The user can design the graphics using the specialized software of the machine. It can also help you edit an existing image.

- The powerful laser can cut and engrave a wide range of objects easily.

- It has a 7 inches large LCD display to control the laser.

- The design and look of the machine are compact and fascinating.

- The internal lighting illuminates the working area.

10. TEN-HIGH 40W Small Desktop CO2 Laser Cutter

TEN-HIGH is a desktop CO2 laser having a large engraving area of 400 x 300mm. There are other versions having different working areas, so the user can choose what he needs to buy. The power is enough for cutting 0-4mm acrylic, but the speed should be slow.

image credit: TEN-HIGH

The machine works with CorelDraw, a feature that professionals would love. It supports JPG, BMP, DXF, CDR, PNG, PLT, TIF, and many others. It is suitable for commonly used non-metals on laser machines and anodized metals.

The catchy feature of the machine is the control panel. There is a small LCD display to show the temperature. Then, there are a few buttons to quickly adjust the laser power as needed.

The machine has an industrial-grade laser module to last for a long time. It also has a red-light positioning system to ensure the correct positioning of the object.

Features:

- Engraving can be done at a high-resolution ratio of 1,000 DPI

- The electric lifting system helps to operate the machine easily.

- The quick buttons on the control panel adjust the power instantly.

- It works on wood, acrylic, fabric, leather, paper, plywood, PVC, silica gel, resin, etc.

Laser Cutter FAQs

What the differences between each laser types?

There are commonly three types of laser cutters and engravers on the market: diode laser, CO2 laser and fiber laser engraver.

Diode Laser

This is a very common type of laser machine, which is usually preferred for small working spaces, homes, and shops. It is compact, beginner-friendly, and affordable, making it an ideal hobby laser cutter.

The laser source is the pump diode, which emits the laser beams. Then, these beams are converged using a convex lens. Usually, the wavelength of a diode laser is 450-455nm, which is called Blue Laser. Plus, you can also get the infrared laser of 1064 nm wavelength in some machines. These wavelengths decide which materials the laser can cut and engrave.

CO2 Laser

A CO2 laser cutter is an ideal laser cutter for small business. It is a bit more expensive than the diode laser machine, but it is still an affordable option.

The laser source in the CO2 laser is the CO2 tube, which contains various gasses, but CO2 is in the highest proportion. When a high potential difference is applied at the electrodes of the tube, laser beams are generated.

This laser is a bit more powerful than diode lasers. Therefore, it cuts and engraves material at a better speed. It can also cuts and engrave a wider range of materials because of its higher wavelength of about 10,600nm.

CO2 lasers are also suitable for new users. They have various advanced features and safety features that ensure easy operation and safety.

Fiber Laser

The last commonly used type of laser is a fiber laser. It uses a fiber optic cable to amplify the laser beams and make them more powerful and highly directed. This laser cutter is much more powerful than the other two, and it is also very expensive.

The fiber optic cable is doped with a certain rare earth metal. Depending on the doping of the cable, a fiber laser is made for various purposes. The desired wavelength is achieved by using the right rare earth metal.

Fiber lasers are very expensive, and they are not suitable for new users or beginners. It is used for limited materials, and the size is also larger than CO2 and diode lasers. However, the power of the laser is immense, which is ideal for specific purposes, such as metal engraving, welding, and cleaning.

It is preferred for large-scale businesses where there is a high speed required, and there are many products or orders to recover the cost of the machine.

What is a laser cutting machine?

Before we get into the best laser cutters, let's understand what's a laser cutting machine. A laser cutting machine is a device that uses a high-powered beam of light to cut or engrave various materials, such as metal, wood, plastic, or paper.

Laser cutting machines work by directing the laser beam that is focused on a small spot on the material. The laser cutter is controlled by a computer program that tells it where to move the laser beam on the material. The computer program can also adjust the power, speed, and frequency of the laser beam to achieve different effects. The laser beam heats up the material until it melts, burns or vaporizes. The result is clean and smooth cuts or engraved patterns that follow the path of the laser beam. Its ability to create precise and intricate shapes, patterns, and designs gives a hobbyist or small business a wealth of possiblities for creativity and product customization.

What is a laser cutter used for?

A laser cutting machine is used for a wide range of purposes. It can cut desired shapes from various materials, allowing DIY lovers or small businesses to make various projects and products, ranging from home decors, gifts, fashion accessories, etc.

A laser cutting machine is not only used for cutting, but it can also do engraving. You can engrave a pattern, name, quote, picture, or anything else on the object, giving it a personal touch or meaning. Thus, laser cutting machines are widely used in customization, especially for gifting.

Is a laser cutter easy to use?

A laser cutter is not difficult to learn. The desktop laser cutters are user-friendly, and you can use them without prior experience or expertise. You only need to learn a few simple things, such as uploading the laser cut files, entering the settings, framing, using the rotary attachment, etc. These are the basics of a laser cutting machine that you can easily learn through tutorials or quick-start guides.

Typically, the machine manufactures provide dedicated laser cutter software. This software is developed according to beginners to make engraving and cutting easier. But even if you want to switch to advanced software, it is not difficult to learn.

Mistakes are part of the learning process. When you start using a laser cutting machine, you will waste some materials. It could be because of selecting the wrong power or speed, selecting the wrong material, the improper focus of the laser, wrong framing, etc. But you learn from these mistakes, and in a few days, you are able to make whatever you want without wasting materials.

Can you make money with a laser cutter?

In a word, YES. You can make money with a laser cutter. A laser engraving and cutting machine allows you to make a wide range of products that can be sold in online stores, trade shows, local stores, etc. There are limitless possibilities, and the sky’s the limit.

Customization is a great business. People love to have customized tumblers, wallets, glasses, pens, shirts, jewelry, decor items, and other things.

Using the laser engraver, you can engrave various materials, such as wood, acrylic, leather, ceramics, glass, metals, and other materials. You can customize different products by engraving names, dates, quotes, or anything according to the customer. You can take any compatible object and engrave it according to their liking.

You can also grab corporate giants, local businesses, and companies. They also require customized products for their customers, visitors, students, and workers. You can make products for them as well and earn a handsome profit.

Furthermore, you can also make unique and appealing items from scratch by using a laser engraving and cutting machine. Users make wall hangings, photo frames, keychains, desk organizers, miniature items, toys, wall clocks, signs, decor items, lamps, and tons of other things that are uncountable. It is completely up to your choice and liking. You can make various items and fill up your inventory with a wide variety of products.

Laser engraving and cutting is an in-demand business. You can start from your home using a simple desktop laser engraver and cutter. With minimal investment, you can start a laser engraving business and earn a handsome amount. Make products after proper research and market them properly. If you do these two things, you will have tons of orders.

What do I consider when buying a laser cutter?

To buy the right laser cutting machine, you need to consider a few important things. These help you compare different machines and choose the best one among them.

Types of the Laser Cutter

The first thing that you need to consider is the type of laser cutting machine. We have discussed three types of laser machines in this article. You need to decide which machine is the right choice for you.

To make the right decision, you need to look at the materials you want to cut or engrave. Then, you will be able to select the best option. For instance, if you want to engrave wood, you can go for a diode or CO2 laser, but a diode laser is cheaper. For metal engraving, fiber laser is the best, but the affordable option could be an infrared laser that can engrave precious metals.

You need to make up your mind regarding the type of laser cutting machine you need. Then, it will be easier to select the right machine. For beginners and experts, a diode laser is the first option, and if they want to target more materials, CO2 lasers are the right choice.

Laser Module Specs

The specifications of laser modules must be checked while comparing the machines. The first thing that you need to check is the laser optical power. We have already discussed what it is.

Secondly, you need to check the measurement of the laser sport. It gives you a better idea of the details that the machine can consider.

You can also check the wavelength of the laser beam and the routing speed of the machine.

Accuracy

Check the movement and repeat positioning accuracy. These are very crucial when it comes to laser engraving. The accuracy should be as good as possible. For some lasers, the movement accuracy is less than 1mm, and the repeat position accuracy is less than 2mm.

Focus and Positioning

The laser is focused on the object to get quick and excellent results. There is a special method of focus in machines. You can check that method; it should be easy enough for beginners and not waste much time. Some laser cutting machines also have a built-in camera to assist with positioning.

Software

You also need to pay attention to the software. Laser machines work on specific software that controls the movement and working of the laser module. The software should be easy enough for the users. Some laser cutting machines are also compatible with third-party software, such as LaserGRBL and LightBurn.

Accessories and Attachments

Laser cutting machines require various accessories and attachments to do various tasks. For instance, there is a need for rotary attachments to rotate cylindrical objects 360 degrees during engraving. You also need an air assist to get better results.

There are various other accessories and attachments, such as an exhaust system, honeycomb panel, enclosure, and extension. Make sure to see whether these are available or not, and it is better to buy the necessary items along with the machine.

Working Area and Height

Check the working area and height of the machine. These dimensions give you an idea of the size of the object that you can process. Sometimes, beginners buy various laser machines, and after delivery, they get to know that the working area or height is very small for their needs. Therefore, it is better to check it in the first place. Moreover, to work on various objects and use attachments, you need to increase the height. Some machines offer height adjustment knobs, legs, or other things that you need to check.

Safety Features

Safety features are very important, but people usually ignore them while looking at the specifications of the laser cutting machine. The powerful laser can start a fire and harm people if it is tipped over. Therefore, there must be some safety features like fire detection, tip-over safety, and emergency stop.

What materials can a laser cutter cut?

The materials that a laser cutitng machine can cut and engrave depend on the type of laser.

1) Materials that Can be Cut with a Diode Laser Cutter

The blue diode laser emits a wavelength of 450-455nm. It is mostly preferred and used for wood and acrylic, and if it is of very high power, it can also engrave metals.

2) Materials that Can be Cut with a CO2 Laser Cutter

CO2 lasers can cut and engrave a wider range of non-metals. It can engrave wood, glass, acrylic, leather, cardboard, stone, paper, rubber, food, and fabric. It can also engrave a few metals.

3) Materials that Can be Engraved with an Infrared Laser Engraver

The infrared laser emits 1064nm radiation, which is ideal for metal and plastic engraving. It can also engrave precious metals, such as gold, silver, platinum, titanium, and copper.

4) Materials that Can be Cut with a Fiber Laser Cutter

Fiber lasers are used for engraving metals. It is a very high-powered laser that can easily engrave hard materials.

What software to use with a laser cutter?

A laser engraving and cutting machine requires a design that you need to import into the software. Once the design is imported, the machine cuts and engraves accordingly. The design has the information on every spot that the machine needs to make on the object.

For designing, you need special software and tools that can help you make graphics. There are multiple software options available, and you can choose them according to your expertise. Some tools are for creating graphics from scratch, and you can do anything according to your creativity. However, some tools are for minimal editing, writing names, and creating simple designs.

Laser cutter software requires special file formats for cutting and engraving. They usually support AI, DXF, SVG, PDF, PNG, JPG, etc. These files are created through special tools and software. Let’s discuss some of them in detail so that you get a complete idea of what you need and how you can get started.

1) Adobe Illustrator

Adobe Illustrator does not need any introduction. It is one of the masterpieces that Adobe has created to date. Whenever we talk about creating vector graphics, Adobe Illustrator comes into our minds in first place.

Adobe Illustrator does not need any introduction. It is one of the masterpieces that Adobe has created to date. Whenever we talk about creating vector graphics, Adobe Illustrator comes into our minds in first place.

There are endless possibilities when you use Adobe Illustrator. You can make almost anything you want and express your creativity. The tools of Adobe Illustrator allow you to create vector graphics from scratch. You can make a unique design of your choice and liking. The vectors that you draw in the software can be engraved by the laser machine.

But Adobe Illustrator is not for beginners. You need to learn how to make vector graphics before you get started. The interface and the tools are not self-explanatory; therefore, you need to watch some tutorials, and it is better to grab a complete course. Moreover, the software is expensive for some users. You need to buy its subscription.

2) Inkscape

If you are looking for a free vector-based graphics tool or software, then Inkscape could be the right option. It is an open-source graphics editor that offers complete features without charging you a penny.

Many users think that Inkscape is a better option because it is free and a bit easier for beginners. Although it requires prerequisites and knowledge to use the tools, you can learn everything easily.

Using Inkscape, you can make incredible vector graphics. It also supports 3D. You can create SVG files using the software and then use it on your engraving machine.

3) Lightburn

Lightburn is an advanced and professional laser engraving and cutting software. It is compatible with a wide range of laser engraver machines that are used for personal as well as commercial purposes.

The software has some advanced tools and settings options that give it an edge over other software.

You can even start and pause engraving if you want, and this exceptional feature is not available in various tools. The settings, layers, modes, and other options are easily visible, and they make engraving and cutting easier. You can easily identify the vectors that are for cutting and engraving. The most important thing is that you can control the result by adjusting the settings in the software.

You can edit vector graphics and make them better according to your liking. You can arrange all the vectors and shapes as you like. Moreover, you can also create simple graphics and shapes from scratch by using its tools.

Lightburn is a paid tool, but you only need to pay once. After getting the key, you can use the software for a lifetime. But keep in mind that it is for the laser machine. It controls the laser cutting machine engraves and cuts according to the imported file. It is not for creating vector graphics.

4) LaserGRBL

LaserGRBL is simple laser engraving and cutting software that is compatible with various laser machines. It is open-source and completely free, which is why many beginners try it out in the first place. The engraver machines that do not offer any native or special software are usually compatible with LaserGRBL because it is open-source and free.

LaserGRBL does not have advanced features. You cannot make graphics from scratch and make special edits. It is a very simple software to get started, but you cannot rely on advanced engraving and cutting. Moreover, it is only available for Windows.

5) XCS

XCS, or xTool Creative Space, is an incredible tool for laser engraving and cutting. It is specifically made for xTool machines, such as D1 Pro and M1. The software is completely free, and the users can enjoy all the features of the tool and engrave/cut whatever they like using the xTool machines.

The software contains the basic designing tools that can help you write the names and add shapes. The best part is that you can draw complete vectors using its vector tool. Therefore, it is a complete tool that you can use to draw and edit graphics. You can cut and engrave by adjusting the images and selecting the optimal settings.

The most important thing is the Project Center. It contains dozens of projects. You can directly open them and start engraving/cutting. It makes things a lot easier for new users. Moreover, there are built-in settings for various materials to get started quickly. It supports a wide range of formats and allows you to use it on Windows and macOS.

What's the best laser cutter?

xTool P2 CO2 laser cutter is defnitely the best laser cutter. Developed after 2 years of research, it boasts two camera systems: one for close-range details and another for full workspace previews. It's powerful, featuring a 55W laser tube and fast operation speeds.

What sets it apart are features like the automatic conveyor feeder for large materials, 3D modeling for curved surfaces, and the ability to do batch engravings. It also has a large working area and can handle varied objects, including round ones like mugs. Safety is prioritized with features like an enclosed design and emergency stop button. The cutter comes with user-friendly software and a supportive online community. In essence, the xTool P2 is a versatile and high-performance tool that offers a seamless user experience.

The difference between a laser cutter and 3D Printer?

3D printers and laser cutters are completely different. They are used for different purposes, but many people who do not know much about them consider them the same machines.

A 3D printer is a machine that can make objects from scratch. For instance, if you need to make a keychain, you can make it by using a 3D printer. It uses spools of the 3D printing filament, which is melted to make the objects. Often people need tailored or special objects, so these can be made with the help of a 3D printer. All you need to do is provide a compatible design to the machine, and then it will melt the filament and direct the head in the required directions to make the object.

On the other hand, a laser cutting machine engraves or cuts existing objects. For instance, you can engrave your name on a keychain or make desired cuts. By using the powerful laser, it removes the particles from the surface of the material, and eventually, you get cutting or engraving results.

What's the difference between a laser cutter and a CNC router?

Many people get confused between a laser cutter and a CNC router. Both then are used for engraving and cutting purposes, but they have different mechanisms.

A CNC router uses various bits, just like a drill machine, to engrave or cut an object. The bit is rotated at a very high speed, and the machine controls its movement. The bits of various sizes are available to get the desired results. There is mechanical contact between the object and the CNC router, and you do not get any burn marks after the process. It is preferred where in-depth carving is needed.

A laser cutter uses powerful laser beams to increase the temperature of the material. Due to the rapid increase in the temperature of the material, the particles are removed from the surface. There is no physical contact between the laser machine and the object. It is preferred for engraving and cutting a wide range of materials. It offers exceptional precision and can work on intricate designs.

Conclusion

The world of laser cutting and engraving offers endless possibilities for hobbyists and small businesses alike. The aforementioned laser cutters and engravers represent some of the best options available, each with its unique features and capabilities. Whether you're pursuing your creative passions or enhancing your business operations, investing in a high-quality laser cutter can significantly elevate your projects. Choose the one that aligns with your specific requirements and embark on a journey of precision, creativity, and limitless possibilities.